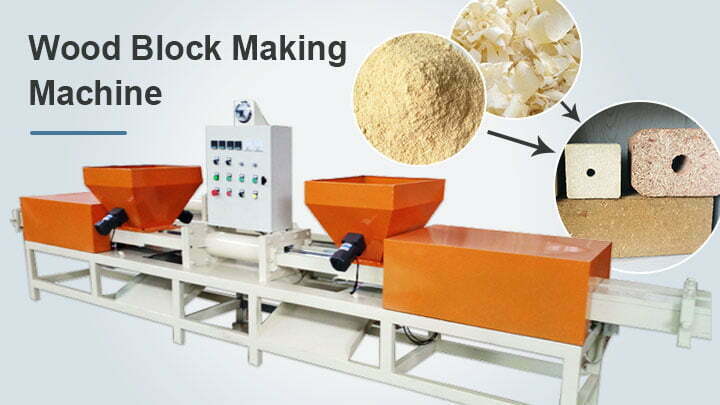

A wood pallet feet compress machine is a machine used to make wooden pallet feet. The wood pallet block machine uses the principle of hot press and hydraulic press to process the sawdust and sawdust raw materials into wooden pallet feet, and the wooden pallet feet are continuously extruded into long strips of specifications by the high temperature and high pressure of the mold.

Why is the wood pallet feet compress machine so popularity

The raw material is the use of recycled wood

Wood pallet feet production and processing to protect the environment of a reuse process, it is the use of some edges of the processing, to achieve the effective recycling of resources, wooden pallets feet pier in the use of the process will inevitably encounter some rainy weather, and wooden pallets feet pier in the rain in the rain can be in a longer period of time to maintain the stability of the structure of the ware, in the water for a long time of immersion on its volume is also less, which is one of his This is one of his characteristics.

The finished product has a large load capacity

The process of making wooden pallet foot pier is through a variety of technologies such as crushing, drying, drying, adhesive, integration, shaping, etc. After a systematic and regular operation, the new product is finally formed, which has the characteristics of beautiful appearance, flat and beautiful, strong and durable, large load capacity, and no moth. The strength of the wooden pallet foot pier made by high temperature and high pressure is comparable to that of ordinary solid wood raw materials, with a beautiful appearance, and the price is far lower than that of wooden pallets. The high-temperature and high-pressure technology of the wooden pallet foot pier can remove any harmful biological substances and does not require any commercial inspection procedures; the unique double-sided wooden plywood effectively improves the horizontal tension; the gumwood mixture is frequently stirred and mixed and extruded, greatly increasing its load-bearing capacity.

Requirements of raw materials for wood pallet feet compress machine

The raw materials of wood chip hot briquetting machines are generally wood recycling supplies, including shavings, sawdust, small wood chips, or other small waste wood, whose size is less than 5 cm and the moisture is about 10~12%. If the raw material does not meet the above requirements, the raw material needs to be crushed and dried to meet the feeding requirements of the wood chip briquette press. Also need to add glue material, such as urea-formaldehyde adhesive, the main component of the glue must be more than 55%.

Wood pallet feet compress production process introduction

1. First, we dry the raw materials to contain 8%-10% moisture, then mix them with glue, and finally the mixed raw materials are pressed into foot piers through the wood chip mat block hot press production line under high pressure and high temperature.

2. The foot pier can be solid or hollow. The wood chip block has high waterproof performance, it can be put into water for 48 hours without splitting and breaking.

3. The wood chip briquette hot pressing line is composed of the main machinery such as a crusher, dryer, glue mixer, wood chip briquette hot pressing machine, and other accessories.