A sawdust dryer machine is a device used to dry sawdust. In the furniture or wood processing industry, a large amount of sawdust and shavings will be produced. These materials are all high-quality biomass fuels. After drying, sawdust can be processed into feed pellets, wooden pallet blocks, etc. but the moisture content of sawdust needs to be controlled during processing. This sawdust dryer machine dries fast and the moisture content after drying is less than 12%.

What raw materials can be processed by a sawdust dryer?

This sawdust dryer machine can dry wood chips, rice husks, shavings, wood chips, ore, sludge, etc. It is widely used in wood chip briquetting, wood chip pellet production, papermaking, furniture production, ore production, and other fields. Due to the large number of raw materials that can be dried, tumble dryers are welcomed by various industries.

Sawdust dryer machine heating method

The heating of the sawdust dryer mainly uses the self-built drying furnace and the biomass fuel to provide the heat source, so that the heat source cost is low and the heat source efficiency is high. It is also possible to utilize natural gas as a heat source. The heat in the sawdust dryer can be recycled, so it is very energy efficient and the drying efficiency is high.

Sawdust dryer machine principle

The material enters the dryer through the feeding device. Since the cylinder rotates slowly in an inclined state, the material moves from the high end to the low end in the axial direction. The lifting plate continuously moves the material in the circumferential direction during the movement. Lifting, throwing, and moving down so that the material and the air can be fully heat exchanged until the drying temperature is below the specified temperature, and the dried material is discharged from the discharging device.

Rice husk dryer parameter

| NO. | MODEL | CAPACITY | POWER | FEED DIAMETER | DIMENSION |

| 1 | SL-800 | 500kg/h | 2.2+7.5kw | ≤5mm | 15000*2600*3800mm |

| 2 | SL-1000 | 1000kg/h | 3+15kw | ≤5mm | 16000*2600*3800mm |

| 3 | SL-1200 | 2000kg/h | 3+18.5kw | ≤5mm | 18000*2800*4000mm |

| 4 | SL-1500 | 3000kg/h | 5.5+22kw | ≤5mm | 19000*3000*4500mm |

There are four models of our sawdust dryer. The larger the model is, the longer the drum is. The output of each model is also different. The output is 500kg/h-3000kg/h, but the material processed by each machine needs to be ≤ 5mm.

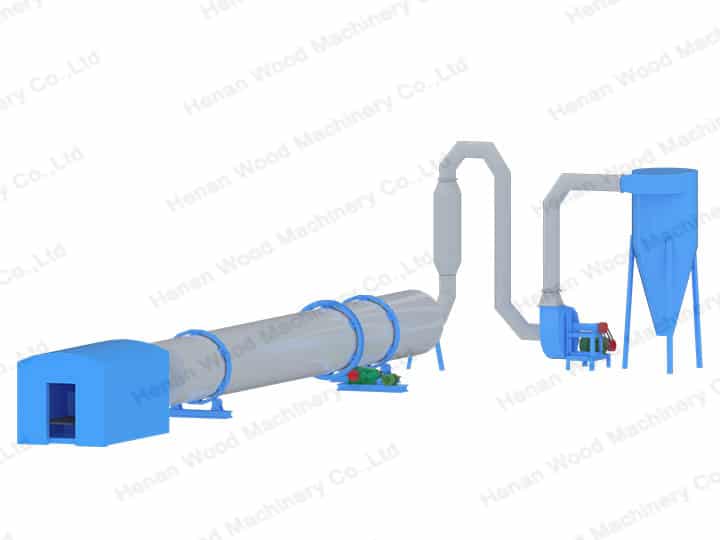

The structure of the sawdust dryer machine

The single-cylinder dryer is mainly composed of a transmission device, a supporting wheel supporting device, a supporting wheel supporting device, a cylinder body, a furnace body, and a sealing device. The main structural features are:

1. The furnace body has 2 to 4 fulcrums (most of which are 3 fulcrums), and it is easy to ensure that the contact surface between the supporting roller and the kiln wheel belt is parallel to the axis of the cylinder during installation;

2. The supporting device adopts a rolling bearing, which greatly simplifies the supporting structure of the supporting roller, which can reduce the wasted power loss during the operation of the kiln, and also make the maintenance and repair more convenient;

3. There is a certain gap between the tire and the cylinder to ensure that the tire is tightened on the cylinder to strengthen the cylinder under normal working conditions;

4. The transmission system adopts a new type of AC variable frequency speed regulation technology. Compared with traditional electromagnetic speed regulation and DC speed regulation, it is more energy-saving and environmentally friendly, and has a large speed regulation range, high efficiency, high-speed regulation accuracy, and stable operation;

5. The furnace body seal adopts a heat-resistant steel scale seal instead of the old labyrinth seal, which makes the sealing performance better, the reliability is higher, the service life is longer, and the replacement is convenient.

Woodchips drum type rotary dryer features

1. The sawdust dryer machine has high production efficiency and a large production capacity.

2. The drying cost is low, which can increase the profit of the product

3. There are many kinds of drying, and there are many uses

4. Simple operation, high drying degree, moisture content can reach <12%