Choose the perfect plan

Wood crush machine, also named Hammer mill or wood shredder. It’s the ideal mechanical equipment for the first process of producing wood flour. It can process wood, branches and forks and other raw materials into sawdust at one time. It has low investment, low energy consumption, high productivity, good economic benefits, and convenient use and maintenance. These processed wood raw materials can be used to make charcoal, plywood, paper, various fillers and other products. Through the wood shredder, you can decompose your wood into products with greater value.

Wood peeling machine, also named wood debarker, is an important part of pulping and papermaking, wood processing, wood chip production and other industries. It is widely used in paper mills, wood chip mills, plywood mills, logging plants, etc. Using the wood peeling machine can greatly save the labor force and reduce the cost of raw material processing.

The wood peeling machine currently produced by our company consists of two models: vertical peeling machine and horizontal peeling machine. There are corresponding machines for different output and quality requirements of users. Our wood peeling machine can effectively remove the bark of the wood, and will not cause too much damage to the wood itself. This machine has strong applicability to wood. It can peel wood of different tree species, diameters, lengths, and shapes. It is perfect supporting equipment for assembly line operations and automated production.

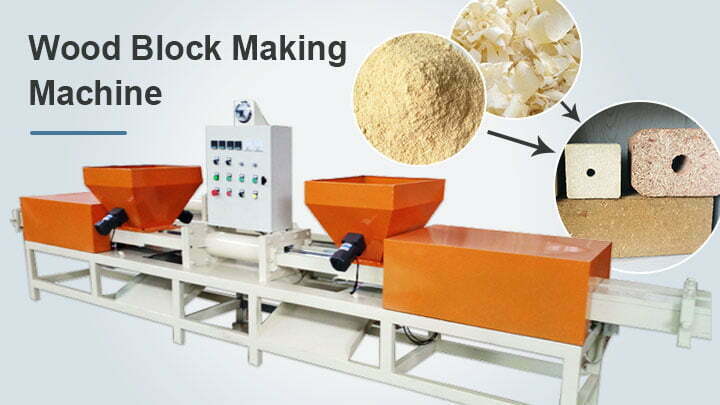

The wood pallet block-making equipment uses waste materials such as wood chips, shavings, straw as the raw materials to produce pallet foot blocks through drying, glue mixing, and a heat press for heating and pressurizing. Most of the raw materials are waste scraps generated during wood processing, so the final pallet foot blocks are also an environmental protection product. Moreover, the wooden pallet block formed after high temperature and high pressure has a hardness comparable to ordinary solid wood materials. The appearance is smooth and flat, it is an ideal material for making foot piers and legs on wooden pallets. Our compressed wood block-making machine can be customized in size according to customer needs, and the pressure and density of the woodblock can also be adjusted. It is a high-quality machine that truly meets the customer’s needs.

Products List

CUSTOMER FIRST

Put the needs and feelings of customers first, considerate service and thoughtful after-sales.

EXCELLENT QUALITY

Complete product supply chain and high-quality products.

PROFESSIONAL GUIDANCE

Intimate guidance throughout the purchase and after-sales process.

MAKE BOLD INNOVATIONS

Technology is the primary productive force, be brave to change and innovate.

Wood crusher

Recently, a businessman from Dubai ordered a wood shredder from us. His company is in the charcoal business. He uses our machines to crush logs and the waste wood scrap to get a lot of sawdust, and then process them into charcoal for sale. After processing, the value of the material has been greatly improved, which is what our machine can bring you.

Hammer Miller Shredder

One of our customer who comes from South East Asia bought a production line from our company. Later, he mentioned in the feedback call that he was very grateful to our products for saving energy and bringing new business opportunities. He would highly recommend our products to his colleagues and friends.

LATEST NEWS

SL-216 wood chipping machine put into use in Luxembourg

Shuliy has successfully exported its wood chipping machine to Luxembourg. The machine boasts a capacity of 5–8 tons/h and is equipped with an automatic feeding and discharging system. It efficiently processes logs and branches with a diameter ≤230mm, producing uniform and adjustable wood chips.

SL-800 timber shaving machine exported to Bolivia for animal bedding production

A Bolivian customer purchased SL-800 timber shaving machine for large-scale production of animal bedding. This equipment has a capacity of approximately 800 kg/h and can process logs and wood scraps, producing soft, uniform wood shavings with high moisture absorption, meeting the needs of the livestock industry.

How to make biomass briquette?

This article introduces the complete process of processing agricultural and forestry waste, such as sawdust and straw, into biomass briquettes using the sawdust briquette machine. It focuses on explaining the working principle, raw material requirements, and equipment advantages of the briquetting machine.