The moulded pallet machine uses the waste wood chips, wood shavings, scraps produced in the wood processing industry as the main raw materials, then through crushing, drying, glue mixing, and hot pressing processed into the wood pallet. After years of research and development, our Moulded pallet machine can produce pallets of various specifications, including the European Standard, American Standard, and other specifications in the world. Moreover, our pallet molds can also be customized in size and shape according to the specifications required by customers. These pallets are mainly used in factories for production turnover or packaging, and they are also ideal supplies for logistics companies and warehousing companies. The pallet is not only a carrier for stacking goods but also a tool for mechanized loading, unloading, and handling. Pallets and forklifts together form the transportation system of the container unit. Therefore, pallets have become an indispensable and important tool in modern logistics systems and are widely used by countries all over the world.

The structure of the pressed wood pallet machine

The pressed wood pallet machine is mainly composed of the mainframe, mold, heating system, and hydraulic system. Among them, the mold is divided into upper and lower molds, and the heating system is respectively combined inside the upper and lower molds. The upper mold is mainly connected with the movable frame, and the lower mold is connected with the bottom frame and the demolding system. This machine has a reasonable design and structure, adopts three-way synchronous positioning, precise balance of mold clamping, and rapid pressurization of liquid filling, which can be fully pressurized in place within 35 seconds. It is convenient and simple to operate. Just spread the wood dust in the mold and press to work button, the machine can automatically complete the whole process of pressing down, pressurizing, limiting pressure, holding pressure, timing, pressure relief, demolding, and rising into place.

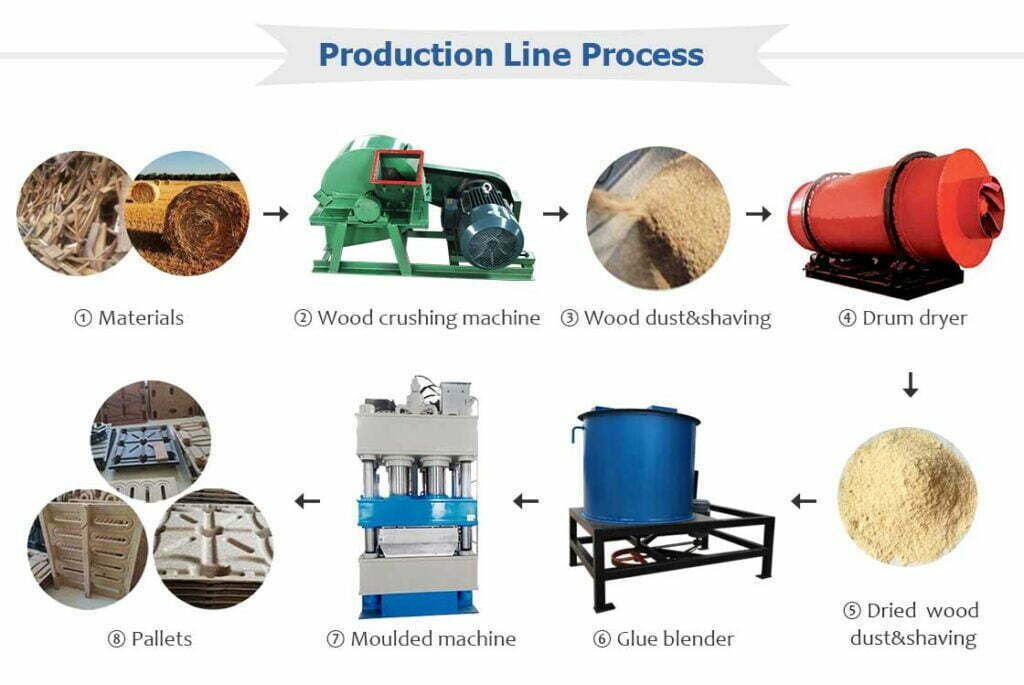

The moulded pallet production process

- Material preparation: Raw materials can use the waste wood, branches, crop straws, waste chemical fibers, etc. Through wood processing equipment (wood crusher or wood shaving machine) to make wood dust or shavings. The thickness of the material between 0.3-0.5mm is the best, too small or too large needs to be sorted out. The processed wood dust and shavings need to be sent to the drum dryer for drying, and the moisture content after drying should be controlled within the range of 2%-3%.

- Glue mixing: In order to prevent the raw materials from being broken, it is not advisable to use a high-speed glue mixing machine. Generally, a roller glue mixing machine is the most used. Send the measured shavings and urea-formaldehyde resin to the glue mixer, and the moisture content of the shavings after mixing should be controlled within the range of 8%-10%.

- Paving and hot pressing: First adjust the upper and lower limit temperature, pressing time, and safety pressure of the thermostat. Then put the mixed material into the mold and spread it out. When the mold temperature reaches the required temperature, the pallet can be pressed.

- Grinding: After the set time is up, the mold opens automatically, and the pressed pallet is automatically ejected from the lower mold. After the operator takes out the pallet, then polishing the corners with a grinder to obtain the finished product.

Characteristics of the pressed wood pallet

- High temperature and high-pressure one-time compression molding, standard size, no metal parts.

- When packaging export commodities, they are exempt from fumigation, quarantine, and visa.

- Optimized design, reasonable structure, good overall performance.

- Meet the requirements of world environmental protection and can be degraded.

- Waterproof, anti-insect, anti-termite, anti-corrosion, not easy to burn.

- Strong bearing capacity, no deformation, and reusable.

- Pallet fork in all sides, easy to use.

- Stacked storage, saving space and convenient for transportation.

- Lightweight and beautiful appearance.

Applications of the moulded pallet

The moulded pallets have a wide range of applications, it’s suitable for building materials, electrical, hardware, food, chemical, furniture, and machinery products together with goods packaging, transportation, turnaround, especially suitable for container vehicles (container cars). It can also be used for mechanized loading and unloading of trains, automobiles, airplanes, and ships, etc. It is an ideal tool for warehousing, transportation, logistics, import, and export trade.

Parameter of the hydraulic press machine for pallet

| Model | Speed | Dimension | Pressure | Weight | Voltage | Model size |

| WD-800 | 220Pcs/Day | 2.3m*1.5m*3.5m | Theoretical pressure:800t Working pressure:25MPa Oil Cyclinder: Φ3604pcs Stroke:400mm Dimension:3.3m*3m*3.2m | 25 Tons | 11Kw | 1200*800mm (Customizable) |

Precautions for equipment safety

- The power supply line is three-phase and five-wire, and the power supply of the control electric box shall be confirmed for the first time. Check whether there is phase loss, too low or too high voltage.

- Control voltage is 220V, must be grounded protection.

- Check whether the over-range protection switch (travel switch) on the equipment is flexible and whether it is stuck.

- Check whether the joints in the electric control box and other electrical components are shaken loose during transportation.

- When all the work in the condition is checked, and everything is normal and correct, the power can be sent.