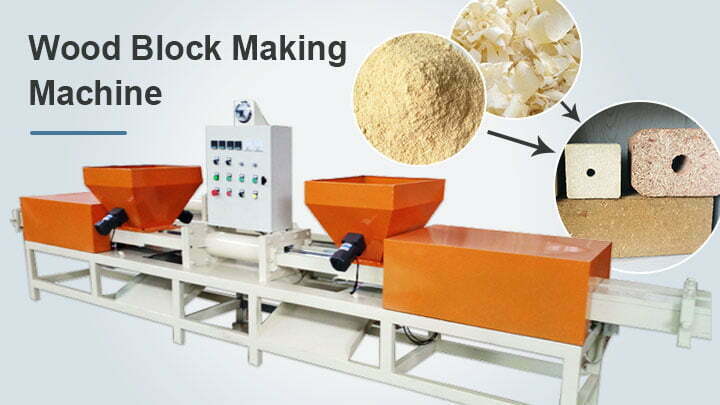

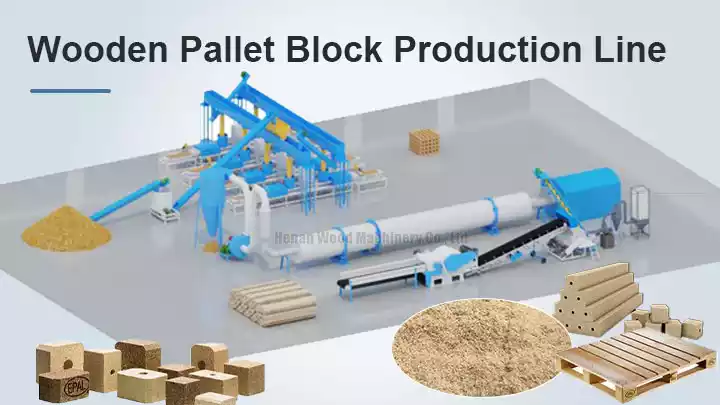

The wood pallet block-making equipment uses waste materials such as wood chips, shavings, straw as the raw materials to produce pallet foot blocks through drying, glue mixing, and a heat press for heating and pressurizing. Most of the raw materials are waste scraps generated during wood processing, so the final pallet foot blocks are also an environmental protection product. Moreover, the wooden pallet block formed after high temperature and high pressure has a hardness comparable to ordinary solid wood materials. The appearance is smooth and flat, it is an ideal material for making foot piers and legs on wooden pallets. Our compressed wood block-making machine can be customized in size according to customer needs, and the pressure and density of the woodblock can also be adjusted. It is a high-quality machine that truly meets the customer’s needs.

The structure of the compressed wood block making machine

Our compressed wood block-making machine is mainly composed of a glue mixing device, control system, hydraulic system, and heating system. Put the dried wood chips or shavings into the glue mixer, and then add the urea-formaldehyde resin for mixing. The material enters from the feed port and enters the hydraulic tank below under the action of the screw. The hydraulic system squeezes the mixed materials into and out of the discharging device, and the discharging device contains a heating system. The lignin in the materials is dissolved under high temperature and high-pressure conditions so that the materials are tightly bonded together, and finally formed at the outlet Wooden strips.

- The control panel can control the hydraulic drive and temperature of the machine

- This part is the hydraulic system, the small round one is a pressure gauge

- This is the unloading device, which has spiral stirring inside to help to unload

- The heating plate is inner this part, the temperature is about 200 degrees

- The final product will discharge here and the pressure can be adjusted by the surrounding screws

- The wooden strips can be equipped with a special block cutting machine according to customer needs

The advantages of the wood pallet block making machine

- The raw materials are waste wood shavings from the wood processing process, and the products made are free of inspection and fumigation, which is an environmentally friendly product.

- The surface of the produced woodblock is smooth and flat, waterproof, not easy to crack.

- The mold can be customized according to the customer’s requirements. The density of the woodblock can be adjusted, up to 700kg / m3, and it is strong and cannot be nailed.

- The equipment structure is simple, easy to operate, in line with the concept of sustainable development, and has a broad market prospect.

Applications of the wood pallet block

The wood pallet blocks are mainly used in the transportation industry, which can play a good protective function. It is widely used in the outer packaging and pallet processing of product transportation in logistics, machinery and electronics, ceramic building materials, hardware and electrical appliances, precision instruments, mining, steel, shipping, and other industries.

Parameter of the woodblock making machine

The machine will be equipped with a hydraulic system and two cutting machines

| Model | Size(mm) | Power(kw) | Capacity(m3/24h) | Density(kg/m3) | Dimension(mm) | Weight(kg) |

| WD-75 | 75*75 | 15 | 3.5 | 550-600 | 4500*750*1200 | 1300 |

| WD-90 | 90*90 | 15 | 4 | 550-600 | 4800*900*1200 | 1500 |

| WD-100 | 100*100 | 16 | 6 | 550-600 | 5000*1000*1200 | 1800 |

| WD-120 | 120*120 | 18 | 9 | 550-600 | 5500*1200*1200 | 2000 |