The Wood Shaving Machine is a new type of wood processing equipment. The log shaving machine can process logs such as sticks, branches, and boards into thin shavings. There is no difference between machine-made shavings and hand-made shavings. The shavings are of moderate size and uniform thickness and can be customized according to customer requirements.

Our wood shavings machine is easy to operate, compared to the traditional operation greatly improves the speed of shavings production, not only saving manpower and time but also improving production efficiency and keeping up with the needs of social development.

The shavings produced by the shaving machine are widely used in particleboard factories, paper mills, biomass energy fuels, pet bedding, poultry breeding bedding, fragile goods transport cushion material, and other industries. It is the ideal log shavings processing equipment for small and medium-sized enterprises and individual wood processing households.

Principle and structure of the wood shaver machine

The wood shaver is mainly composed of the main body of the frame, the inlet and outlet, the blade, the motor, and so on. After the raw material enters through the inlet, it is cut by the blade and discharged through the outlet.

The whole process is very fast and can be mass-produced. The size and thickness of the shavings can be adjusted by the length of the blade and the degree of inclination of the blade to meet the needs of different customers.

Our power unit has two methods: A motor and a diesel generator. The position of the inlet and outlet can be adjusted or lengthened, and it can be equipped with a conveyor belt for easy transportation.

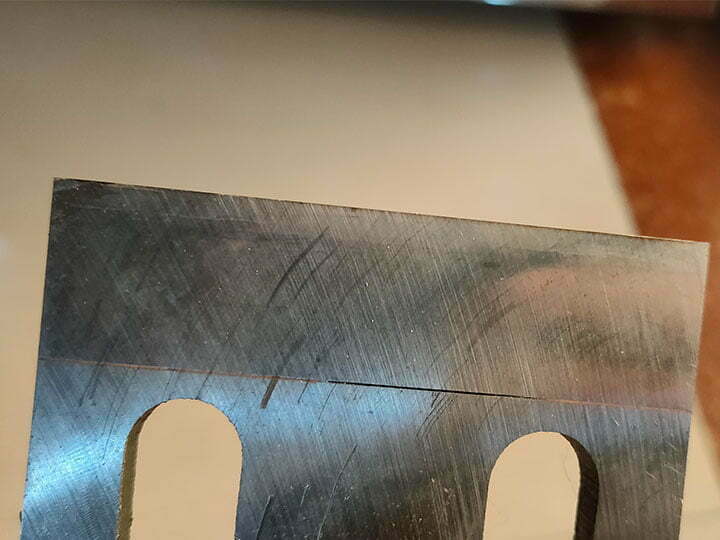

Introduction of the blade

The blade plays an important role in the whole shaving process. The size and thickness of the wood shaving can also be changed by adjusting the length and inclination angle of the blade. High-quality blades are more conducive to the production of high-quality shavings.

Our blades are made of carbon steel, which not only has a long service life but also is easy to disassemble and install. We also have a special knife sharpener. If you feel that the blade is not sharp or damaged, you can re-install and use it after the sharpener is repaired (we have a special disassembly and installation video tutorial to provide).

Applications of the wood shavings machine

The log shavings produced by our log shaving machine have a very wide range of applications. It can be used to make plywood, as a raw material for wood pulp paper in paper mills, as filling materials for fragile goods transportation in transportation companies, bedding materials for pets at home, bedding nests in poultry farms, biomass energy, etc.

Parameter of the wood shavings machine

| MODEL | CAPACITY | INPUT SIZE | POWER |

| WD-420 | 300KG/H | 6cm | 7.5kw |

| WD-600 | 500KG/H | 12cm | 15kw |

| WD-800 | 1000KG/H | 16cm | 30kw |

| WD-1000 | 1500KG/H | 20cm | 55kw |

| WD-1200 | 2000KG/H | 24cm | 55kw |

| WD-1500 | 2500KG/H | 32cm | 75kw |

Customer case of our wood shaver machine

Two months ago, we had a customer from New Zealand who purchased a WD-600 wood shaver from us. He owned a horse farm, and the stuffing of the stables cost him a great deal of money every year.

He uses wood shavings from abandoned trees and wood scraps from his farm to make his nest. This not only helps him get rid of the pile of discarded wood, but it also saves him a lot of money on nest stuffing.