The band saw machines are a kind of sawing equipment that uses a ring-shaped endless band saw blade as a saw tool, which is wound on two saw wheels to make a one-way continuous linear movement to saw wood. It is mainly composed of a bed, saw wheel, band saw blade, saw blade guide device, worktable, guide plate, etc. The bed is made of cast iron or steel plate welding. It is used for log splitting, splitting board square wood, and large panel saw It can also be used to cut unedged boards into full-edged boards or squares.

Three different bands saw types

According to the position of the band saw blade and the different materials used, the band saw is divided into three different types: vertical band saw, horizontal band saw, and round wood sliding table saw. All band saws are equipped with CNC machine tools, which can cut wood precisely. Band saws generally use a pneumatic compression mechanism to ensure that there is no deviation in the wood-cutting process. Each band saw has its unique shock absorption system to ensure that the band saw blade does not jitter when cutting, and to ensure the quality of the cut sheet.

Vertical Band Saw

The vertical band saw has an upper saw wheel and a lower saw wheel. Generally, the lower saw wheel is the driving wheel, and the saw wheel is the driven wheel. On this pair of saw wheels, a thin steel belt with serrations on one side is a hung-band saw blade, When the saw wheel rotates, the band saw blade also rotates, so the saw teeth on the saw blade continue to move rapidly, and the wood is sawed when it comes in contact with it. Due to structural reasons, vertical band saws are generally fixed in a certain place, and the work efficiency is very high, which is suitable for some large wood processing plants.

| Model | WD-S3000 | WD-S5000 | |

| Saw wheel diameter | 1600mm | 1250mm | |

| Max sawing wood diameter | 800mm | 1000mm | |

| Motor power | 30KW | 45KW | |

| Sawing thickness setting | CNC | ||

| wood clamping model | Electric | Hydraulic | |

| Wood rotation | Hydraulic roller on the ground | ||

| Max sawing wood length | 4000mm | 6000mm | |

| The length of the track | 10M | 18M | |

| Weight | 5000KG | 10000KG |

Horizontal Band Saw

The only difference between the structure of the horizontal band saw and the vertical one is that the upper and lower saw wheels have become left and right saw wheels. Horizontal band saws can be equipped with movable wheels and diesel engine models, which are convenient to move to work outdoors. The diameter of the woodcut by the horizontal band saw machine is larger than that of the vertical band saw machine. It is only necessary to widen the gauge between the tracks to cut wood with a larger diameter.

| Model | WD-1500 | WD-2500 |

| Saw wheel diameter | 1000mm | 1070mm |

| Max sawing wood diameter | 1500mm | 2500mm |

| Motor power | 37KW | 55KW |

| Sawing thickness setting | 350mm | 450mm |

| Max sawing wood length | 6000mm | 6000mm |

| Weight | 4500kg | 5500kg |

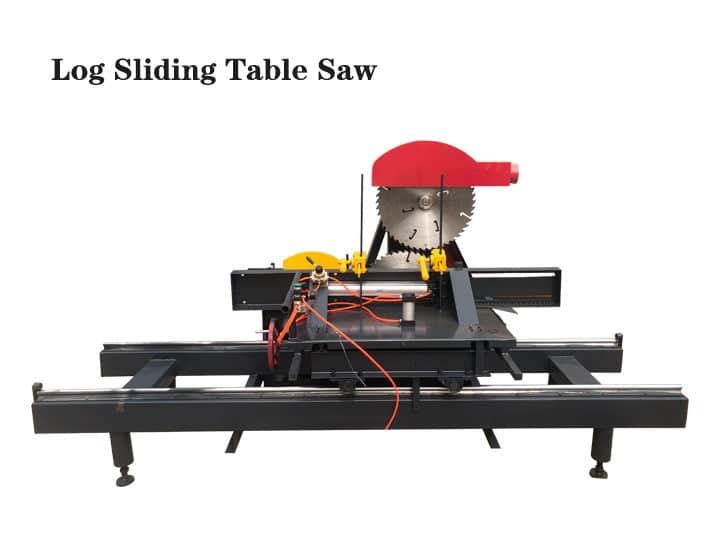

Log Sliding Table Saw

The sliding table saw can be customized for two operating modes, CNC or manual, according to customer needs, and can also be equipped with movable wheels to facilitate outdoor operations. The structure of the sliding table saw is different from the above two band saws. It no longer uses a band saw blade for cutting, but directly uses two hard band saw wheels for cutting. The cutting range of the sliding table saw is the diameter of the band saw wheel, which is more suitable for some small wood processing plants.

| Model | WD-300 | WD-400 | WD-500 |

| Max sawing wood length | 4000mm | 4000mm | 4000mm |

| Max sawing wood diameter | 3000mm | 4000mm | 5000mm |

| Motor power | 7.5KW*2 | 11+7.5kw | 11KW*2 |

| Dimension | 8000X1600X1600mm | ||

| Weight | 750KG |

Rules for the safe use of band saws

- The thickness of the band saw blade should be compatible with the matched band saw wheel. Avoid using large-thick saw blades for small wheels, which may cause breakage and injury.

- The saw tooth should be sharp, and the tooth depth should not exceed 1/4 of the width of the saw blade.

- The welding of the band saw blade should be firm and flat, the joints should be more than 3 woods, the length between the two joints should be more than 1/5 of the total length, and the thickness of the joints should be basically the same as the thickness of the saw blade.

- Strictly control the transverse cracks of the band saw blade, and the excessively long cracks should be cut off and re-welded.

- The track of the sports car of the large band saw machine should be straight, with travel switches at both ends, and warning bars should be set on both sides of the sports car. How to equip the safety device of the circular saw.