Wooden pallets are mainly used for stacking, handling, and transporting goods. After using wooden pallets, it is convenient for mechanized loading and unloading, which improves the efficiency of handling. The pressed wood pallet production line uses wood as raw material to produce wooden pallets.

Two types of wooden pallets

There are two types of wooden pallets, one needs to be nailed, and the other is mixed with wood chips and glue. The following is a glued wood pallet machine.

Features of pressed pallets

Wood chips and glue are mixed under high temperatures and high pressure. In the process of making plywood, pressed pallets must go through high temperatures and high pressure above 200°C to combine the veneers into plywood. Therefore, wooden pallets are sterilized at high temperatures. Therefore, pressed pallets do not need fumigation or heat treatment certificates and procedures when exporting. Glued wood pallets have excellent waterproof and moisture-proof properties.

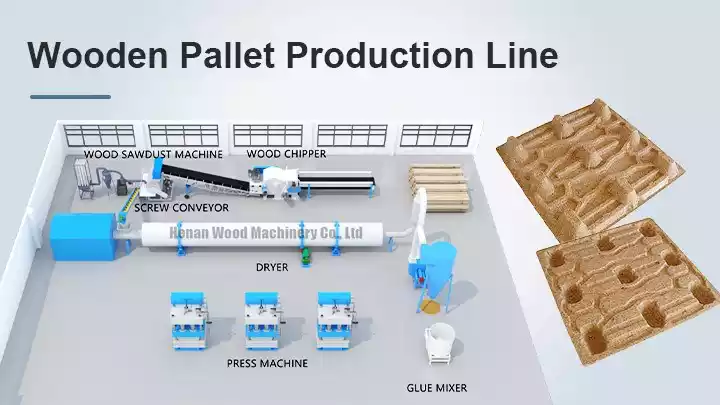

Pressed wood pallet production line

The pressed wood pallet production line is complete equipment for making wooden pallets. The raw materials are mainly wood, wood chips, wood scraps, sawdust, etc.

The production process of the pressed wood pallet production line is: through wood crushing → making wood chips → drying wood chips → mixing with glue → making wooden pallets.

wood chipper

DRUM CHIPPER: crush wood logs into wood chips

A wood chipper is a machine that can break wood into wood chips, and a wood chipper is a simple crushing of wood.

| Model | SL-216 |

| Capacity | 5t/h |

| Input size | 230*500mm |

| Max Diameter of Feeding log | 250mm |

| Knife roller speed | 590r/min |

| Number of blades | 4pcs |

| Material of blade | 55crsi |

| Diameter of the Knife roller | 650mm |

| Size of the finished product | 50*50mm |

| Power of the Main motor | 55kw |

| Power of Feeding motor | 4kw*2 |

| Power of The oil pump motor | 1.1kw |

| Weight | 4300kg |

Sawdust making machine

WOOD SAWDUST MACHINE: crush wood chips into sawdust

The final raw material for the production of wooden pallets is wood chips, which need to be crushed into wood chips using wood chip production machines

| Model | SL-500 |

| Capacity | 500kg per hour |

| Input size | 230*500mm |

| Hammer number | 40pcs |

| Main motor | 22kw |

| Diameter of Dust remover | 800mm |

| Final product size | 10mm |

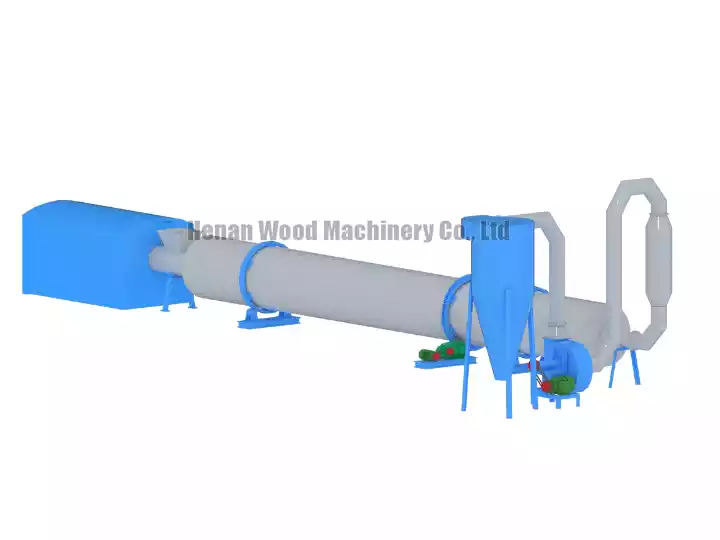

Sawdust dryer

WOOD SAWDUST MACHINE: reduce the moisture of sawdust

The moisture content of wood chips for the production of wooden pallets should be less than 10%, so a dryer is needed for drying.

| Model | SL-D800 |

| Power | 3kw |

| Fan power | 5.5kw |

| Capacity | 500-600kg/h |

| Diameter | 800mm(D) |

| Thickness | 8mm |

| Weight | 1800kg |

Glue and sawdust mixer

| Model | SL-900 |

| Power | 7.5kw |

| Dimension | 1.5*1*1.4m |

| Diameter | 900mm |

| Weight | About 300kg |

| Glue | Urea-formaldehyde resin glue |

GLUE MIXER: mix sawdust with glue

The production of glued wooden pallets requires mixing wood chips and glue, and the glue mixer can quickly and fully mix the two.

Wooden pallet forming machine

Wooden pallet forming machine:

The wooden pallet forming machine heat-presses the tray by hot pressing, and the high temperature also has the effect of sterilization.

| Model | SL-1000 |

| Power | 15kw |

| Pressure | 1000tons |

| Capacity | Produce one pallet need 4-5 minutes(can control by yourself ) |

| Dimension | 1.9*1.3*4m |

| Weight | 21000kg |