The blade is the most important part of the wood crushing machine, but it is also the most wearable part. The quality of the knives will directly determine the production effect and service life of the wood crusher. When we choose the wood processing machine, we should also pay attention to the quality of the blades. High-quality blades can have better processing effects and higher production efficiency whether it is crushing, shavings, or chipping. Inferior blades are prone to wear and tear under high-intensity use scenarios, and in severe cases, they may damage the machine. Our blades are made of high-quality carbon steel, carbon steel has good wear resistance and heat resistance, which can meet the needs of continuous high-intensity work.

The reason of blade wear

Blade wear is generally divided into two situations, natural wear and unnatural wear.

- Natural wear means that the cutting edge of the blade gradually changes from sharp to blunt during normal use. In the case of natural wear, the middle part of the cutter shaft will generally wear more severely than on both sides.

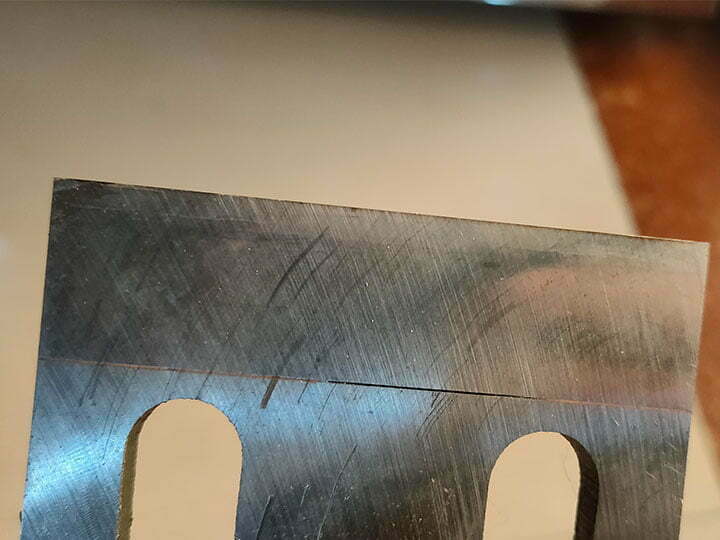

- Unnatural wear means that the hardness of the material during normal processing exceeds the hardness that the tool can accept. For example, metal materials such as iron plates and steel nails are mixed into the wood, or the processed wood is too dry. In this case, the blade will appear chipped or cracked. At this time, it is necessary to replace the blade in time to avoid the processed material not meeting the requirements or damaging the machine.

Stages of blade wear

Blade wear is divided into three stages, the initial wear stage, the normal wear stage, and the sharp wear stage.

- Initial wear refers to the roughness, micro-cracks, oxidative carbonization and other defects on the surface of the new blade when the blade is first used. And at this time, the blade is sharper, the contact area with the wood is small, and the stress is greater, so the wear at this stage is faster. Our blades are ground by a knife sharpener before use, which can effectively avoid wear at this stage.

- The normal wear stage is actually natural wear, and the wear at this stage is relatively slow and uniform. The degree of wear increases linearly with the use time, and this stage lasts for a long time.

- Rapid wear stage. When the blade is worn to a certain extent, the blade is no longer sharp. At this time, when cutting wood, the temperature will increase sharply, and the wear speed will also increase. so that the blade is damaged and loses its cutting ability. We must avoid this situation during use, and the blade should be sharpened or replaced in time after a period of use.

The maintenance of blads

In the process of using the blade, there are also some methods that can help us to make the blade have a better production effect and service life.

- We must avoid mixing metal particles into the material, which will cause great damage to the blade.

- After handling some muddy or viscous materials, clean the blades in time to avoid affecting work efficiency due to attachments on the blades. And some of the sawdust, wood chips and other substances remaining in the shredder also need to be cleaned in time to avoid affecting the quality of the finished product

- Keep lubrication during use, and the material can not be too dry. Appropriate humidity can play a role in cooling the blade during operation.

- We also have a special knife sharpener. If you feel that the blade is not sharp or damaged, you can re-install and use it after the sharpener is repaired (we have a special disassembly and installation video tutorial to provide).

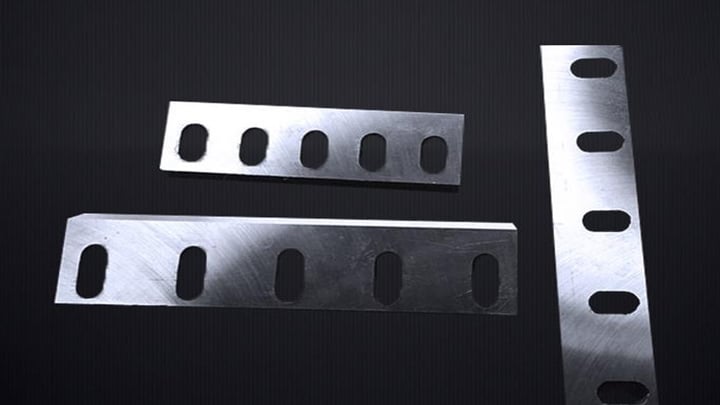

Blade plate

Blade

Blades

Blade grinder

If you need a wood crusher with a good production effect, the best way is to go to the factory for an on-site inspection. Our company sincerely invites you to come to our factory. We have accumulated a lot of production experience in wood processing equipment and listened to the practical suggestions of users. We also provide users with dust collectors, conveyor belts, knife sharpeners, and other ancillary equipment, sincerely for the sake of users, and welcome customers to visit our factory.