The German client in this collaboration is the head of a clean energy plant. His goal in purchasing the biomass briquette press machine is to utilize agricultural waste resources to produce high-density fuel briquettes for home heating and industrial boilers.

What are the customer’s needs?

Through communication, we understood the client’s requirements for the biomass briquette press machine as follows:

- Raw material types: sawdust, rice husks, straw.

- Fuel briquette specifications: 50mm in diameter, adjustable length, complete combustion, and high strength.

- Daily production target: Approximately 1000 kg/day.

- Operational requirements: Simple and easy to operate.

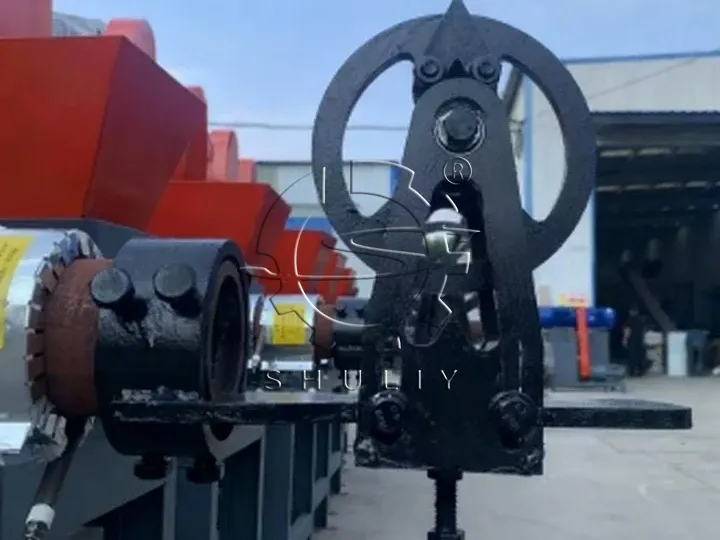

Solution: SL-50 biomass briquette press machine

To meet our customers’ needs, we recommended the SL-50 bimoass briquette press machine. This machine has the following features:

- High-efficiency pressing, with a fuel rod formation rate of up to 98%.

- It can process wood chips, rice husks, straw, and various agricultural and forestry waste materials.

- Compact structure, easy operation, and can be operated by a single person.

Customer order list

Ultimately, the customer ordered the SL-50 sawdust briquette making machine and cutter. The final order list is as follows:

| Item | Parameters | Qty |

Biomass briquette press machine | Model: SL-50 Power: 18.5 kW Capacity 250–300 kg/h Voltage: 400 V, 50 Hz, 3 Phasen Size: 1.63*0.64*1.64m Weight: 630 kg | 1 |

Cutter | / | 1 |

Production results and customer feedback

One month after the biomass briquette press machine was put into use, the German customer reported a significant improvement in production efficiency: the average daily output increased by approximately 30%, and the yield of fuel rods improved by about 15%. Furthermore, the sawdust briquette machine was easy to operate, saving on labor costs. In short, the customer was very satisfied with this collaboration.

Contact us immediately!

Are you also looking for an efficient biomass briquette press machine, just like our German customers? If so, please contact us today, and we will provide you with the right machine and customized solutions to meet your needs!