The wood flour machine, also named fine wood dust crusher, is a kind of equipment that makes fine wood powder from wood dust after crushing processing. The wood flour machine is composed of coarse crushing and fine crushing, wind screening and conveying devices. The motor drives the main shaft of the crusher to run at high speed, which produces a high-intensity mechanical force on the material. Finally, through the steps of screening, recycling, and dust removal, to get high-quality wood flour. Compared with the traditional ball mill, it has the advantages of small size, lightweight, low power consumption, no pollution, and low price. The fineness of the product can be adjusted arbitrarily between 20-325 mesh, up to 1250 mesh. It is a multi-functional powder milling machine.

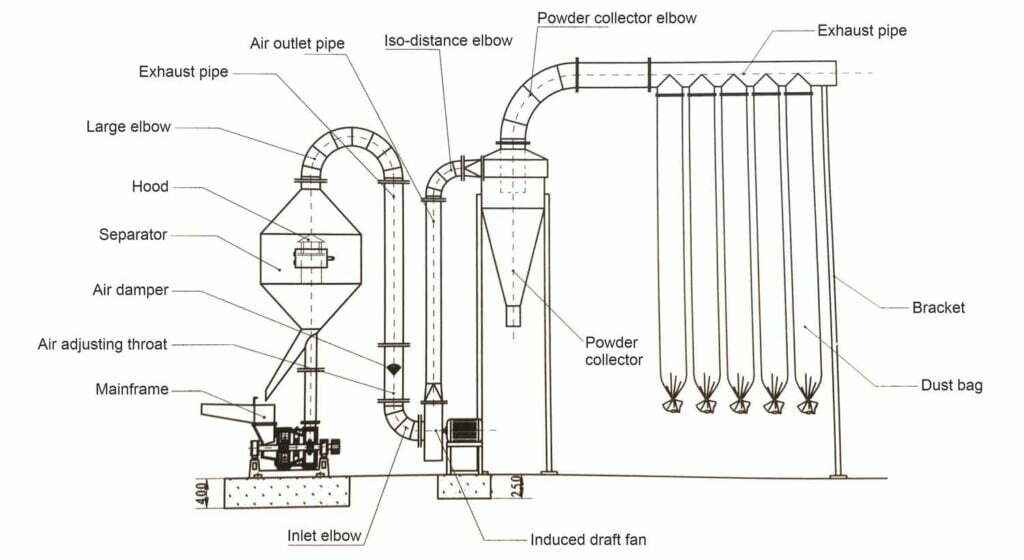

The principle and structure of the wood flour machine

After the wood dust enters the feed inlet, they are crushed by the high-speed rotating hammer. Then, under the action of the fan airflow sorting, the materials with high specific gravity will pass through the return port and enter the feed port for secondary crushing. And the materials with low specific gravity will enter the next-level screen box through the air duct. Qualified wood powder is discharged into the powder collecting bag through the discharge port, and lighter dust is discharged into the dust collecting bag.

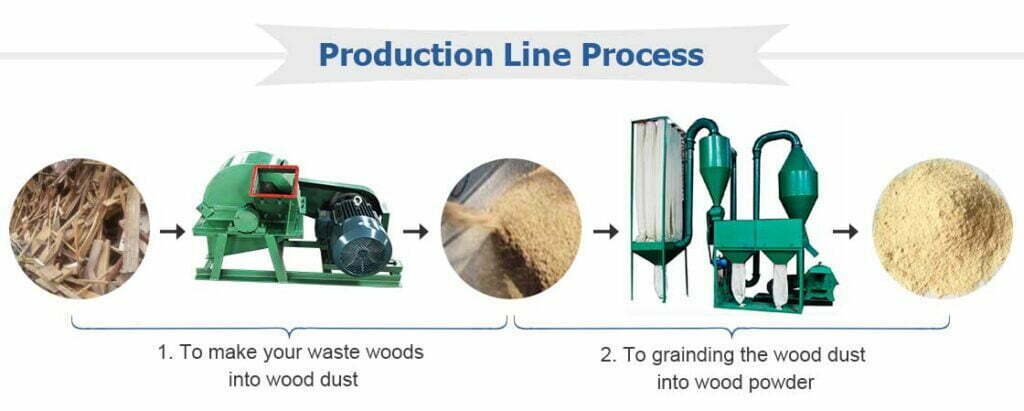

Process of the wood powder poduction

Method for adjusting flour fineness

In the process of using the wood flour machine, different products also have requirements for the fineness of wood flour. For example, the fineness of wood flour used in papermaking is generally about 80-100 mesh, and the wood flour used in incense is generally required to range from 80-120 mesh. While wooden leather has higher requirements for wood flour fineness, generally above 200 mesh. The following is to provide you with the method of adjusting the fineness of wood flour with this machine. The following four methods can adjust the fineness of wood flour between 20-325 mesh.

- Adjust the oblique blade: Adjust the blade left and right along the axial direction. The smaller the gap between the oblique blade and the tapered surface, the smaller the fineness, and vice versa.

- Adjust the hood: Decreasing the hood will increase the fineness, otherwise, it will be thicker, even removing the hood.

- Adjust the air volume: opening the air damper to reduce the air volume can make the particle size of the wood flour fine, and vice versa. It should be noted that if the air volume is too small, the return nozzle is easy to spray powder.

- Adjust the fan blades of the main engine: If necessary, reduce the fan blades in the casing to improve the fineness.

Applications of the wood powder

Our wood powder machine is suitable for chemical, graphite, pharmaceutical, fuel, building materials, mining and other industries. It can be used to process carbon toner, gypsum powder, lime powder, shell powder, emery, etc. It also can be used to process Chinese herbal medicine, wheat, soybeans, corn and other raw materials. The final product wood powder can be used to make Buddha incense, mosquito incense, toilet paper, wooden leather, and some chemical applications.

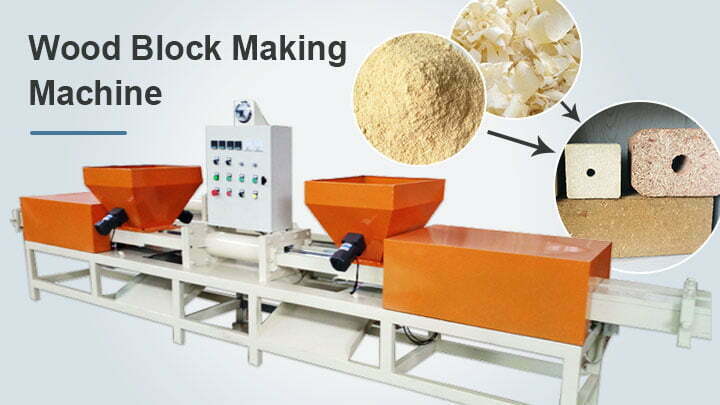

Factory machine display

The maintenance of the wood powder machine

- Strictly check whether each part of the machine meets the installation requirements before starting. The speed of the machine is high, the feet need to be installed firmly, and good lubrication is required.

- When starting, start the fan first and then turn on the main engine. When stopping, stop the main engine first and then stop the fan.

- In the process of adding materials, the size of the materials should be kept as uniform as possible, and it is strictly forbidden to feed metal objects.

- During use, the motor load should not be overloaded. The grinding degree of the blade and the grinding plate should be checked frequently. If the blade is found to be seriously worn, it should be replaced in time.