Wood crush machine also named wood shredder. It’s the ideal mechanical equipment for the first process of producing wood flour. It can process wood, branches forks, and other raw materials into sawdust at one time. It has low investment, low energy consumption, high productivity, good economic benefits, and convenient use and maintenance. These processed wood raw materials can be used to make charcoal, plywood, paper, various fillers, etc. Through the wood shredder, you can decompose your wood into products with greater value. Want more information about this machine? Welcome to consult.

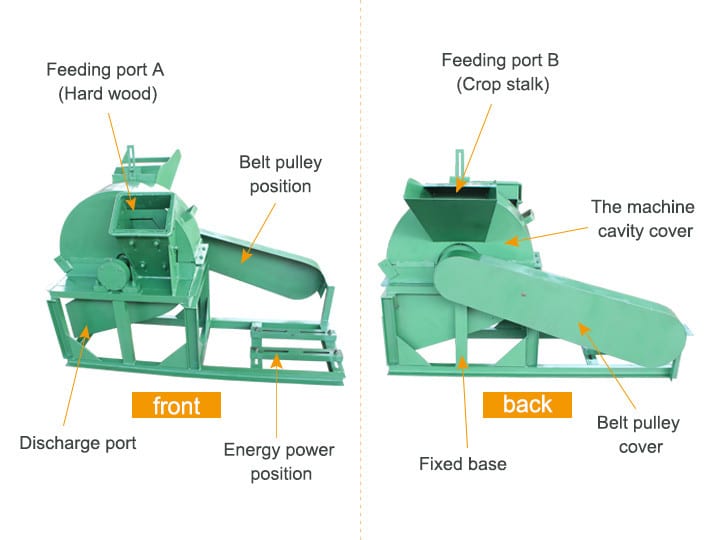

The structure and principle of the wood crusher

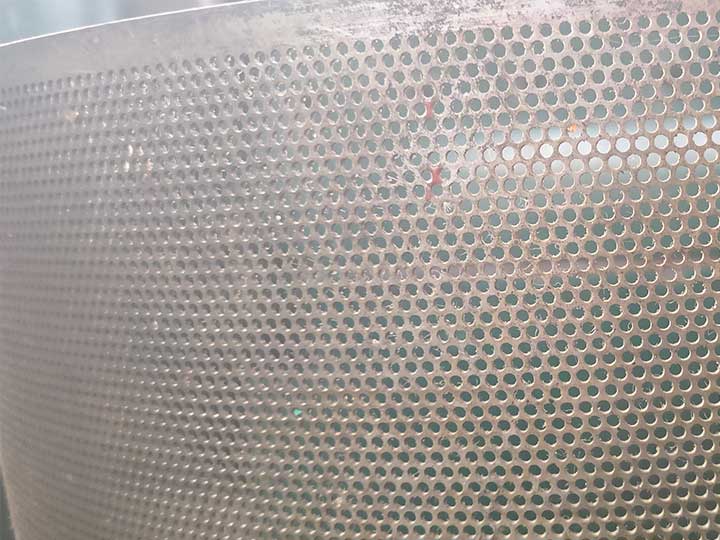

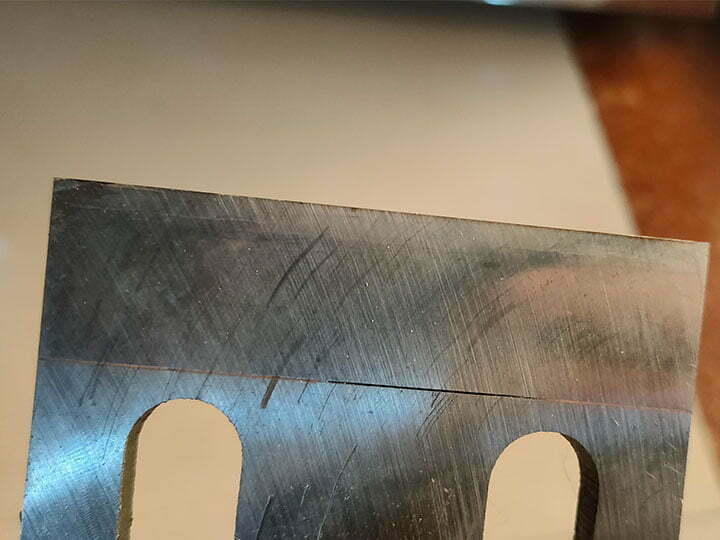

Our wood crushing machine is mainly composed of a base, feed ports, blades, hammers, screen mesh, and a discharge port. Feeding port A is more suitable for harder wood, bamboo, nutshells, and other materials. Feeding port B with a larger entrance is more suitable for soft materials that do not need to be cut by blades, such as straw, thatch, straw, corn stalks, and other crops. After the raw material enters the machine through the feed port, the harder wood will be cut into small pieces by the blades (the soft material that enters the B port does not need to pass through the blades). Then the materials will be beaten, squeezed, and rubbed by the high-speed rotating hammer. If the material processed by the hammer is smaller than the diameter of the screen mesh, it will be discharged through the discharge port under the action of the high-speed hammer, and the larger piece of material will continue to be beaten until it meets the standard.

The feature of the wood shredder

The position of the inlet and outlet can be adjusted or lengthened, and it can be equipped with a conveyor belt for easy transportation.

According to the output size of the customer, we can also customize the corresponding larger machine

The screen mesh can be customized according to the size of the material required by the customer. We have a variety of sizes of mesh to meet different needs.

The blade and hammer are vulnerable parts. You can buy multiple sets of blades at once and they are easy to replace

The blade can also be equipped with a corresponding sharpener

It can be used with sand clones and dust removal equipment to reduce dust pollution

Our power unit has two methods: Motor and diesel generator

The power unit can be equipped with a control cabinet to ensure electrical safety

Compact structure, easy to operate, all of all rotors pass an accurate dynamic balancing test, less vibration during running.

The base can be customized as a wheeled or fixed base.

The double-mouth wood pulverizer overcomes the problem that the single-mouth wood chip machine adapts to the hard material but does not adapt to the soft material.

Raw materials and applications of wood crush machine

Our company’s multi-functional wood crushing special equipment a double-mouth wood crusher, which can crush wood, pine, miscellaneous wood, fir, raw bamboo, and bark, and also can be used for bamboo, thatch, corn stalk, Straw and so on. And the processed wood raw materials can be used to make charcoal, plywood, paper, various fillers, etc.

Technical data of the wood shredder

| Model | Capacity | Outlet size | Power |

| SL-420 | 600-800KG/H | 0.3-0.8cm | 7.5-11kw |

| SL-500 | 1000-1500KG/H | 0.3-0.8cm | 18.5kw |

| SL-600 | 1500-2000KG/H | 0.3-0.8cm | 30kw |

| SL-700 | 2000-2500KG/H | 0.3-0.8cm | 37kw |

| SL-900 | 2500-3000KG/H | 0.3-0.8cm | 55kw |

| SL-1000 | 3000-4000KG/H | 0.3-0.8cm | 75+7.5kw |

The delivery case of the wood crusher

Recently, a businessman from Dubai ordered a wood shredder from us. His company is in the charcoal business. He uses our machines to crush logs and the waste wood scrap to get a lot of sawdust, and then process them into charcoal for sale. After processing, the value of the material has been greatly improved, which is what our machine can bring you.

Related video about the wood crushing machine

Attention points in the use of wood shredder

- Switch on the power and check whether the steering is correct.

- When installing and changing the cutter, extend the knife edge 2-4mm from the cutter plate plane, and then tighten the bolt. If the pressure bolt thread buckle is found to be worn out, it should be replaced immediately to prevent a slip of the knife disc nut. 3. Change the stretching degree of the knife, must be the same stretching knife length.

- Depending on the length of the knife, the particles can not reach the ideal, changing the different pore sizes of the rottweiler.

- It is strictly prohibited to put wood with stones and nails into the machine to avoid damaging the knife and the inner part.

- Pay attention to checking the hammer bolt, If found loose, immediately tighten it, the hammer and bolt wear seriously, and should be replaced.

- The sharpening Angle is 28-30& DEg;, is strictly prohibited to grind a convex surface, the convex surface will cause the steel blade to break off or partially unpeel steel.

- Frequently used machines should be checked for lack of bearing butter. Butter should be refilled 3-4 hours, not too much.

Maintenance of the wood crushing machine

- 1. The bearing should be filled with butter in a timely manner. The bearing should be filled with butter once in 3-4 hours for continuous operation.

- 2. After using the triangle belt for a period of time, the tightness should be adjusted again and it is advisable to decrease by 6-10mm.

- 3. Clean the machine every day after work, check whether there are cracks or other problems, and repair the machine in time.