The drum chipper can cut logs, branches, boards, waste veneers, bamboo, cotton stalks and other non-wood fiber stems into a certain size of sheet material. Our industry wood chipper is special equipment for preparing various high-quality wood chips, which is used in the wood chip production and export bases of paper mills, particleboard mills, and fiberboard mills. Our drum chipper machines have advanced machine structure, high quality of cutting sheet material, wide adaptability of raw materials, convenient operation and maintenance.

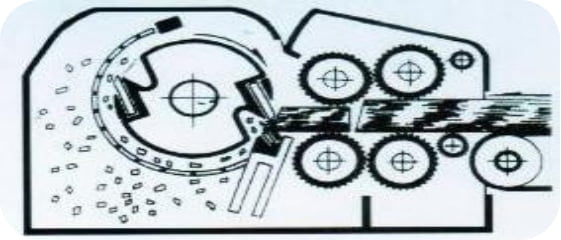

Principle of the drum chipper

The wood is fed from the feed port. When the wood is contacted to the cutting blade, the cutting is followed by the high-speed rotation of the cutting blade. The cutting mechanism is a rotating drum with a plurality of flying knives mounted thereon, and the flying knife rotates. Wood is processed into wood chips. There is a plurality of squares through holes on the outer edge of the drum. The cut pieces pass through the mesh holes and are discharged at the bottom. The large pieces will be cut again in the machine.

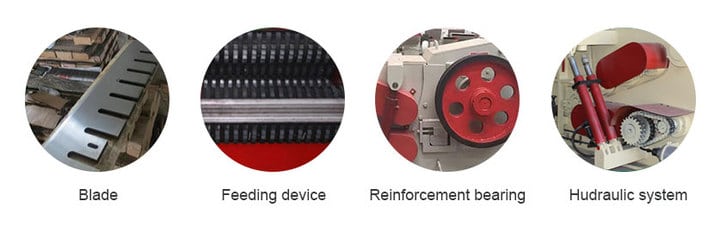

The structure of the drum chipper

The drum chipper is composed of a body, a knife roll, an upper and lower feeding mechanism, a hydraulic system, a feeding device and the like.

- The body: welded by high-strength steel plate, is the support foundation of the whole machine.

- Knife roll: Two or three or four flying knives are installed on the knife stick. The fly knives are fixed on the knife roll by a pressure block.

- Hydraulic system: It is supplied to the cylinder by the oil pump, and the cover can be activated to facilitate the replacement of the blade; the upper feeding roller assembly can be lifted during maintenance, which is convenient for adjusting the gap between the flying knife and the bottom knife and the disassembly and assembly of the comb plate.

- Upper and lower feeding mechanism: consists of feeding interface, upper and lower feeding rollers and feeding gap adjusting mechanism. The wood entering from the feeding interface is pressed by the upper and lower feeding rollers and is fed to the cutting mechanism at a certain speed. Controls the size of the cutting chips; when processing thick wood, it is adjusted by the feed gap mechanism.

Advantages of our chipping machine

- Strong adaptability: Due to the integrated assembly technology of the main engine and the self-discharging system and the main engine and the agricultural machinery base, it is unnecessary to make the main engine foundation and the main motor foundation. , Climate and other external conditions.

- Time-saving: Because the foundation is not required, users can save 10-15 days of precious time. The equipment can be installed and put into production immediately after it is shipped. Generally, it can be completed in 1-2 days, which saves 2/3 of the usual time.

- Save money: Because it is not used as a foundation, it can save users basic material and financial resources. According to different models, it can save 3,000 to 10,000 yuan at a time.

- Flexible and convenient: Because there is no need to install in the extrusion, the installation and debugging of the equipment is very simple, which greatly improves the installation speed and flexibility. Due to the secondary discharging device, users can change the discharging direction and use it flexibly according to their needs. Because there is no foundation and restriction, users can easily change the working place according to their needs and are no longer restricted by the foundation.

The materials and applications of wood chipper

All of the tight and slice materials suit our machine! You can put materials like bamboo, logs, slice board, branch wood and so on. The non-wood fiber stems are also suiting our drum chippers, such as cotton stalk, sugar cane, reed, etc.

Cases of high-volume chipper

We used to have a customer from Sri Lanka, who bought a product line with a big size drum chipper. He had a paper mill in the local area. Near his factory was largely farmland, which always had lots of discarded wheat stalks. Our customer, the shrewd businessman, chose to collect these discarded wheat stalks and put them into our machine. Then the stalk was processed into paper pulp, which helped him get more raw materials of paper than before, and he could save money for buying materials of paper.

Parameter of the wood chipper

| Model | WD-218 | WD-216 |

| Knife Quantity | 2 | 2 |

| Feeding size | 300*680 mm | 230*500 mm |

| Capacity | 10-15 t/h | 5-8t/h |

| Raw material dimension | ≤300 mm | ≤230 mm |

| Wood chip size | 25 mm(Adjustable) | 25 mm(Adjustable) |

| Main power | 110 kw | 55 kw |

| Weight | 8600 kg | 5600 kg |

| Feeding inlet conveyor | 6 m | 6 m |

| Outlet conveyor | 8 m | 8 m |

| Packing Size | 3105*2300*1650 mm | 2735*2200*1200 mm |