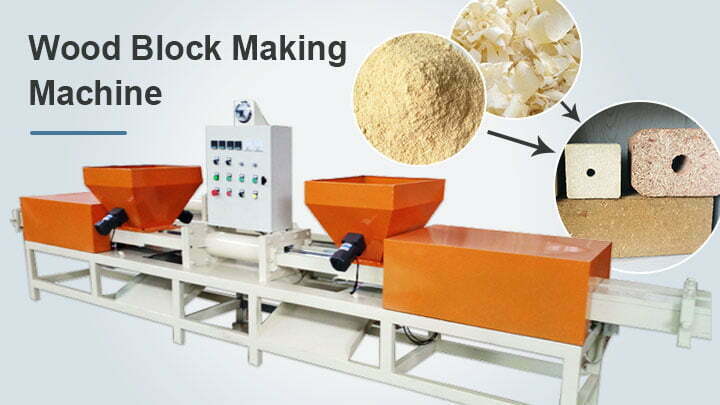

Die Anlagen zur Herstellung von Holzpalettenblöcken nutzen Abfallmaterialien wie Holzspäne, Späne und Stroh als Rohstoffe zur Herstellung von Palettenfußblöcken durch Trocknen, Leimmischen und eine Heißpresse zum Erhitzen und Unterdrucksetzen. Bei den meisten Rohstoffen handelt es sich um Abfallabfälle, die bei der Holzverarbeitung anfallen, sodass die fertigen Palettenfußblöcke auch ein Umweltschutzprodukt sind. Darüber hinaus weist der nach hoher Temperatur und hohem Druck geformte Holzpalettenblock eine Härte auf, die mit gewöhnlichen Massivholzmaterialien vergleichbar ist. Das Erscheinungsbild ist glatt und flach, es ist ein ideales Material für die Herstellung von Fußstützen und Beinen auf Holzpaletten. Die Größe unserer Druckholzblock-Herstellungsmaschine kann je nach Kundenwunsch individuell angepasst werden. Auch der Druck und die Dichte des Holzblocks können angepasst werden. Es handelt sich um eine hochwertige Maschine, die die Bedürfnisse des Kunden wirklich erfüllt.

Der Aufbau der Maschine zur Herstellung von Pressholzblöcken

Unsere Maschine zur Herstellung von Pressholzblöcken besteht hauptsächlich aus einer Leimmischvorrichtung, einem Steuersystem, einem Hydrauliksystem und einem Heizsystem. Geben Sie die getrockneten Holzspäne oder -späne in den Leimmischer und geben Sie dann das Harnstoff-Formaldehyd-Harz zum Mischen hinzu. Das Material tritt durch die Zufuhröffnung ein und gelangt unter der Wirkung der Schnecke in den darunter liegenden Hydrauliktank. Das hydraulische System drückt die gemischten Materialien in die Austragsvorrichtung und aus dieser heraus, und die Austragsvorrichtung enthält ein Heizsystem. Das Lignin in den Materialien wird unter Bedingungen hoher Temperatur und hohem Druck aufgelöst, so dass die Materialien fest miteinander verbunden werden und schließlich am Austritt Holzstreifen entstehen.

- Über das Bedienfeld können der hydraulische Antrieb und die Temperatur der Maschine gesteuert werden

- Dieser Teil ist das Hydrauliksystem, der kleine runde Teil ist ein Manometer

- Dabei handelt es sich um die Entladevorrichtung, die im Inneren über eine Spiralrührvorrichtung verfügt, die das Entladen erleichtert

- In diesem Teil befindet sich die Heizplatte, die Temperatur beträgt etwa 200 Grad

- Hier tritt das Endprodukt aus und der Druck kann über die umliegenden Schrauben eingestellt werden

- Die Holzleisten können je nach Kundenwunsch mit einer speziellen Blockschneidemaschine ausgestattet werden

Die Vorteile der Maschine zur Herstellung von Holzpalettenblöcken

- Die Rohstoffe sind Abfallholzspäne aus dem Holzverarbeitungsprozess, und die hergestellten Produkte unterliegen keiner Inspektion und Begasung, was ein umweltfreundliches Produkt darstellt.

- Die Oberfläche des hergestellten Holzblocks ist glatt und flach, wasserfest und reißt nicht leicht.

- Die Form kann je nach Kundenwunsch individuell angepasst werden. Die Dichte des Holzblocks kann auf bis zu 700 kg/m eingestellt werden3, und es ist stark und kann nicht genagelt werden.

- Die Gerätestruktur ist einfach, leicht zu bedienen, entspricht dem Konzept der nachhaltigen Entwicklung und bietet eine breite Marktaussicht.

Anwendungen des Holzpalettenblocks

Die Holzpalettenklötze werden hauptsächlich in der Transportindustrie verwendet und können eine gute Schutzfunktion erfüllen. Es wird häufig bei der Umverpackung und Palettenverarbeitung des Produkttransports in den Branchen Logistik, Maschinen und Elektronik, keramische Baumaterialien, Eisenwaren und Elektrogeräte, Präzisionsinstrumente, Bergbau, Stahl, Schifffahrt und anderen Branchen eingesetzt.

Parameter der Holzschnittmaschine

Die Maschine wird mit einem Hydrauliksystem und zwei Schneidmaschinen ausgestattet

| Modell | Größe (mm) | Leistung (kW) | Kapazität (m3/24h) | Dichte (kg/m3) | Abmessung (mm) | Gewicht (kg) |

| WD-75 | 75*75 | 15 | 3.5 | 550-600 | 4500*750*1200 | 1300 |

| WD-90 | 90*90 | 15 | 4 | 550-600 | 4800*900*1200 | 1500 |

| WD-100 | 100*100 | 16 | 6 | 550-600 | 5000*1000*1200 | 1800 |

| WD-120 | 120*120 | 18 | 9 | 550-600 | 5500*1200*1200 | 2000 |