เครื่องย่อยไม้มีชื่อว่าเครื่องย่อยไม้ซึ่งเป็นของอุปกรณ์ซีรีย์การแปรรูปไม้ เครื่องทำลายไม้สามารถตัดเศษไม้ ไม้ไผ่ กระดาน และวัสดุหนังเป็นเศษไม้ขนาดเล็กตามข้อกำหนดเฉพาะได้ ผลิตภัณฑ์ขั้นสุดท้ายสามารถใช้เป็นวัตถุดิบในกระบวนการผลิตพาร์ติเคิลบอร์ด แผ่นใยไม้อัด เยื่อกระดาษ และอุตสาหกรรมอื่นๆ และยังสามารถใช้เป็นเชื้อเพลิงพลังงานชีวมวลโดยตรงอีกด้วย เครื่องย่อยไม้ของเรามีข้อดีในการใช้งานที่หลากหลาย การตัดเศษไม้คุณภาพสูง ใช้งานง่าย และประสิทธิภาพการผลิตสูง เป็นอุปกรณ์ที่เหมาะสำหรับลูกค้าในการผลิตเศษไม้คุณภาพสูง

หลักการและโครงสร้างของเครื่องย่อยไม้

เครื่องย่อยไม้ส่วนใหญ่ประกอบด้วยฐาน ทางเข้าและทางออก ใบมีด ตัวเครื่อง และระบบควบคุมไฟฟ้า เครื่องสามารถปรับใบมีดตัดได้ตามความต้องการของลูกค้าเพื่อผลิตเศษไม้ที่มีข้อกำหนดและความหนาต่างกัน หลังจากที่ไม้เข้าสู่ตัวเครื่องผ่านทางช่องฟีด มอเตอร์จะขับเคลื่อนโรเตอร์ให้หมุนด้วยความเร็วสูง ไม้ถูกตัดเป็นเศษไม้ที่มีขนาดสม่ำเสมอภายใต้การทำงานของใบมีดหมุนความเร็วสูง จากนั้นจึงรีบไปที่ช่องระบาย ประสิทธิภาพการผลิตของเครื่องย่อยไม้นั้นสูงมาก และสามารถป้อนและระบายได้อย่างต่อเนื่อง ซึ่งโดยพื้นฐานแล้วสามารถตอบสนองความต้องการของลูกค้าสำหรับการผลิตขนาดใหญ่

ข้อดีของเครื่องทำลายไม้

- โรเตอร์ใบพัดดีไซน์ใหม่ ใบมีดสามารถเปลี่ยนได้ง่าย

- สามารถเปิดฝาครอบห้องบดได้ สะดวกในการบำรุงรักษาและเปลี่ยนใบมีดได้

- ความจุสูงกว่ารุ่นดั้งเดิม ขนาดการป้อนที่ใหญ่ขึ้น สามารถตัดท่อนไม้ที่มีเส้นผ่านศูนย์กลาง 230-500 มม.

- ตำแหน่งของทางเข้าและทางออกสามารถปรับหรือขยายได้ และสามารถติดตั้งสายพานลำเลียงเพื่อความสะดวกในการขนย้าย

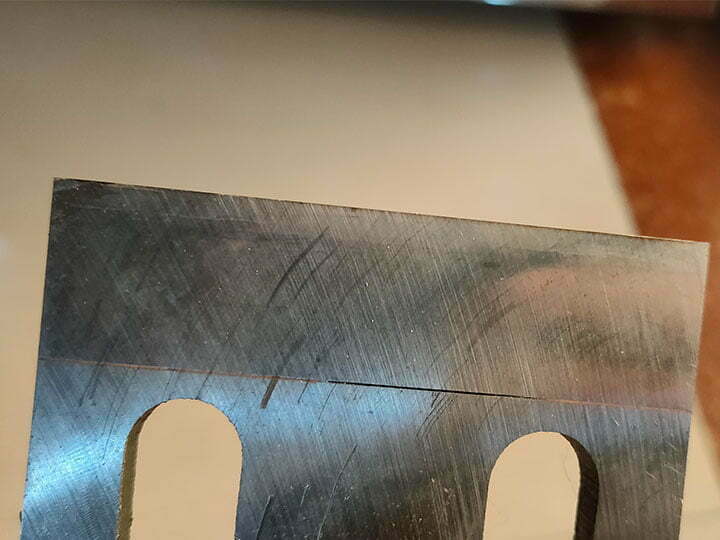

บทนำของใบมีด

ใบมีดมีบทบาทสำคัญในกระบวนการโกนทั้งหมด ขนาดและความหนาของการโกนไม้สามารถเปลี่ยนได้โดยการปรับความยาวและมุมเอียงของใบมีด ใบมีดคุณภาพสูงเอื้อต่อการผลิตขี้กบคุณภาพสูงมากกว่า ใบมีดของเราทำจากเหล็กกล้าคาร์บอน ซึ่งไม่เพียงมีอายุการใช้งานยาวนาน แต่ยังถอดประกอบและติดตั้งได้ง่ายอีกด้วย เรายังมีเครื่องลับมีดแบบพิเศษอีกด้วย หากคุณรู้สึกว่าใบมีดไม่คมหรือชำรุด คุณสามารถติดตั้งใหม่และใช้งานได้หลังจากซ่อมแซมที่ลับมีดแล้ว (เรามีวิดีโอสอนการถอดแยกชิ้นส่วนและการติดตั้งพิเศษให้)

การใช้งานเครื่องย่อยไม้

วัตถุดิบหลักที่ตัดโดยเครื่องย่อยไม้คือไม้ที่มีเส้นผ่านศูนย์กลางเล็ก การเก็บเกี่ยวไม้ และเศษเหลือจากการแปรรูป (เช่น กิ่งก้าน แผ่นพื้น แผ่นระแนง แกนไม้กลม แผ่นไม้อัดเสีย เศษไม้ ฯลฯ ) และยังสามารถใช้เพื่อตัดวัสดุที่ไม่ใช่ - วัสดุไม้ (เช่น อ้อย กก ไม้ไผ่ ฯลฯ) วัตถุดิบถูกตัดเป็นเศษไม้ขนาดเล็กตามข้อกำหนดที่เกี่ยวข้อง ซึ่งใช้เป็นวัตถุดิบสำหรับพาร์ติเคิลบอร์ด บอร์ดความหนาแน่นปานกลาง แผ่นใยไม้อัด การทำกระดาษ เชื้อเพลิงชีวมวล ฯลฯ

พารามิเตอร์ของเครื่องย่อยไม้

| แบบอย่าง | อัตราผลตอบแทน(T) | กำลังรองรับ (กิโลวัตต์) | น้ำหนักเดี่ยว (กก.) | ความเร็วแกนหมุน (รอบ / นาที) | หมายเลขใบมีด | ขนาดทางเข้าป้อนอาหาร (มม.) |

| WD-400 | 1 | 7.5 | 160 | 650 | 3 | 150×150 |

| WD-600 | 2 | 15 | 380 | 600 | 3 | 180×150 |

| WD-800 | 5 | 30 | 520 | 550 | 4 | 200×200 |

| WD-1000 | 8 | 37 | 950 | 550 | 4-6 | 230×250 |

| WD-1200 | 12 | 75 | 2000 | 500 | 4-6 | 330×300 |

| WD-1400 | 15-16 | 110 | 2800 | 500 | 4-6 | 400×400 |

| WD-1600 | 20 | 132 | 4600 | 500 | 4-6 | 480×450 |

| WD-1800 | 25 | 160 | 6500 | 500 | 4-6 | 550×550 |

สต๊อกโรงงาน ของเครื่องสับไม้