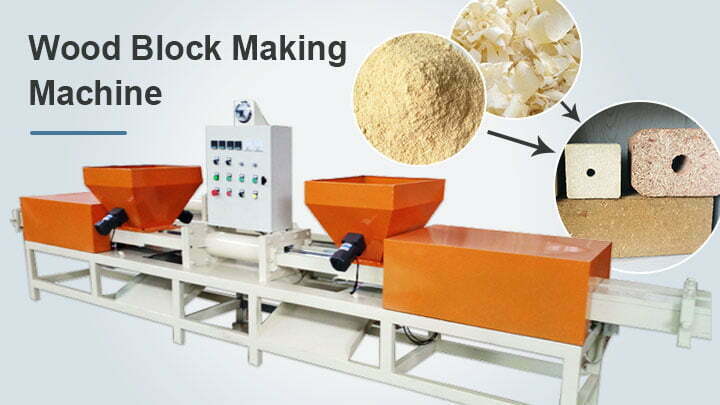

목재 팔레트 발 압축 기계는 목재 팔레트 발을 만드는 데 사용되는 기계입니다. 목재 팔레트 블록 기계는 핫 프레스와 유압 프레스의 원리를 사용하여 톱밥과 톱밥 원료를 목재 팔레트 발로 가공하며, 목재 팔레트 발은 금형의 고온 및 고압에 의해 지속적으로 긴 규격의 스트립으로 압출됩니다.

목재 팔레트 발 압축 기계가 왜 그렇게 인기가 있습니까?

원료는 재활용 목재를 사용

재사용 공정의 환경을 보호하기 위한 목재 팔레트 피트 생산 및 가공은 자원의 효과적인 재활용을 달성하기 위해 가공의 일부 가장자리를 사용하는 것이며, 프로세스 사용 시 목재 팔레트 피트 부두는 필연적으로 비가 오는 날씨에 직면하게 됩니다. , 그리고 나무 팔레트 발 부두는 비에 젖어도 도자기의 구조 안정성을 유지하기 위해 오랜 시간 동안 있을 수 있으며, 물에 오랫동안 담그는 양도 적습니다. 그의 것 중 이것은 그의 것 중 하나입니다 특성.

완제품의 적재 용량이 큽니다.

목재 팔레트 발판을 만드는 과정은 파쇄, 건조, 건조, 접착, 일체화, 성형 등의 다양한 기술을 거쳐 체계적이고 정기적인 작업을 거쳐 최종적으로 아름다운 특성을 지닌 새로운 제품이 탄생하게 됩니다. 외관, 평평하고 아름답고 강하고 내구성이 있으며 부하 용량이 크고 나방이 없습니다. 고온 고압으로 만든 목재 팔레트 발 교각의 강도는 일반 단단한 목재 원료와 비슷하며 외관이 아름답고 가격은 목재 팔레트보다 훨씬 저렴합니다. 목재 팔레트 발교의 고온, 고압 기술은 유해한 생물학적 물질을 제거할 수 있으며 상업적인 검사 절차가 필요하지 않습니다. 독특한 양면 목재 합판은 수평 장력을 효과적으로 향상시킵니다. 검우드 혼합물은 자주 저어지고 혼합되고 압출되어 내하력이 크게 향상됩니다.

목재 팔레트 피트 압축 기계의 원료 요구 사항

우드 칩 열간 연탄 기계의 원료는 일반적으로 부스러기, 톱밥, 작은 우드 칩 또는 기타 작은 폐목재를 포함하는 목재 재활용 용품이며 크기는 5cm 미만이고 수분은 약 10~12%입니다. 원료가 위의 요구 사항을 충족하지 않으면 목재 칩 연탄 프레스의 공급 요구 사항을 충족하기 위해 원료를 분쇄하고 건조해야 합니다. 또한 요소-포름알데히드 접착제와 같은 접착제 재료를 추가해야 하며 접착제의 주성분은 55% 이상이어야 합니다.

목재 팔레트 피트 압축 생산 공정 소개

1. 먼저 원료를 건조시켜 8%-10% 수분을 함유시킨 후 접착제와 혼합하고 마지막으로 혼합된 원료를 고압 및 고온 하에서 우드 칩 매트 블록 핫 프레스 생산 라인을 통해 발 교각으로 압착합니다.

2. 발 교각은 단단하거나 속이 비어 있을 수 있습니다. 우드칩 블록은 방수 성능이 뛰어나 48시간 동안 물에 넣어도 쪼개지거나 부서지지 않습니다.

3. 우드 칩 연탄 핫 프레싱 라인은 분쇄기, 건조기, 접착제 믹서, 우드 칩 연탄 핫 프레싱 기계 및 기타 액세서리와 같은 주요 기계로 구성됩니다.