Ahşap kırıcı, ahşabı verimli bir şekilde işlemek için iş verimliliğini büyük ölçüde artırabilen bir tür makinedir. Toplumun sürekli gelişmesiyle birlikte, çoğu ahşap işleme işinin özel gereksinimlerini karşılayabilecek parçalayıcıların türleri ve stilleri giderek daha mükemmel hale geldi. Odun parçalayıcılar için farklı besleme yöntemlerinin de makinenin çalışması üzerinde büyük etkisi olacaktır, bu nedenle herkesin ahşap kurutucuların farklı besleme yöntemlerini anlaması gerekir.

İki besleme yöntemi odun kırıcı

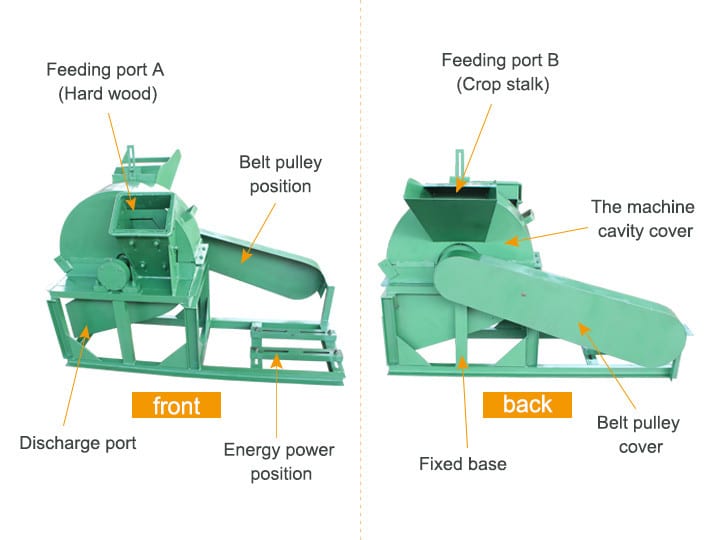

Ahşabı beslemenin iki ana yolu vardır. Birincisi, batmak ve beslenmek için malzemenin yerçekimine güvenmek ve siloya girdikten sonra bıçakların ve çekiçlerin etkisi altında ezilmektir.

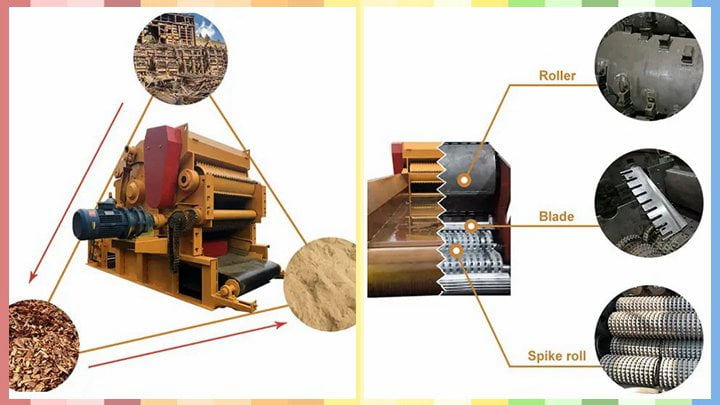

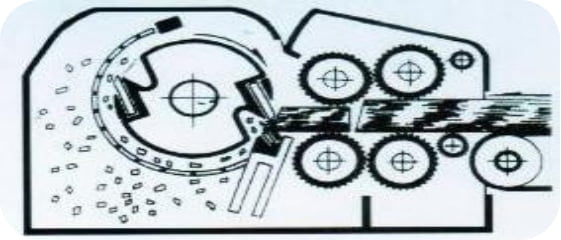

Diğeri ise hidrolik akıllı zorlamalı besleme sistemidir. Malzeme besleme portundan girdikten sonra, haddeleme silindirlerinin etkisi altında belirli bir hızda ileri doğru itilir. Bu yapı çoğunlukla tamburlu odun yongalayıcılar gibi büyük makinelerde kullanılır.

Ağaç öğütücülerin çoğu, bir yandan iş verimliliğini büyük ölçüde artıran, diğer yandan da işçilik maliyetlerinden tasarruf sağlayan yardımcı besleme için konveyör bantlarla donatılmayı seçecektir. Taşıma bandı ayrıca kırılmış malzemeleri doğrudan taşıma kamyonuna da götürebilir. Tam bir ağaç kırma üretim hattı için taşıma sistemi bunun vazgeçilmez bir parçasıdır.