Pallet za mbao hutumiwa hasa kwa kuweka, kushughulikia, na kusafirisha bidhaa. Baada ya kutumia pallets za mbao, ni rahisi kwa upakiaji na upakiaji wa mitambo, ambayo inaboresha ufanisi wa utunzaji. Mstari wa uzalishaji wa godoro la mbao ulioshinikizwa hutumia kuni kama malighafi kutengeneza pallet za mbao.

Aina mbili za pallets za mbao

Kuna aina mbili za pallets za mbao, moja inahitaji kupigwa misumari, na nyingine imechanganywa na chips za mbao na gundi. Ifuatayo ni mashine ya godoro ya mbao iliyo na glued.

Vipengele vya pallets zilizoshinikizwa

Serutan kayu dan lem dicampur pada suhu tinggi dan tekanan tinggi. Dalam proses pembuatan plywood, pallet tekan harus melewati suhu tinggi dan tekanan tinggi di atas 200°C untuk menyatukan lapisan veneer menjadi plywood. Karena itu, pallet kayu disterilkan pada suhu tinggi. Karena itu, palet tekan tidak memerlukan sertifikat serta prosedur fumigasi atau perlakuan panas saat diekspor. Palet kayu yang direkatkan memiliki sifat tahan air dan tahan kelembapan yang sangat baik.

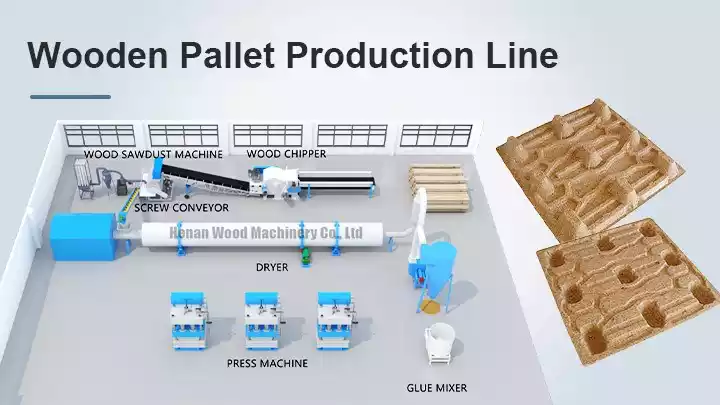

Mstari wa uzalishaji wa godoro la mbao ulioshinikizwa

Mstari wa uzalishaji wa godoro ya mbao iliyoshinikizwa ni vifaa kamili vya kutengeneza pallet za mbao. Malighafi ni hasa mbao, chips mbao, mabaki ya mbao, machujo ya mbao, nk.

Mchakato wa uzalishaji wa mstari wa uzalishaji wa godoro la kuni ulioshinikizwa ni: kwa kusagwa mbao → kutengeneza chipsi za mbao → kukausha chips mbao → kuchanganya na gundi → kutengeneza pallet za mbao.

mtema kuni

DRUM CHIPPER: menghancurkan batang kayu menjadi serpihan kayu

Kipasua kuni ni mashine inayoweza kupasua kuni kuwa vipande vya mbao, na mtema kuni ni upasuaji rahisi wa kuni.

| Mfano | SL-216 |

| Uwezo | 5t/h |

| Ukubwa wa pembejeo | 230*500mm |

| Upeo wa Kipenyo cha logi ya Kulisha | 250 mm |

| Kasi ya roller ya kisu | 590r/dak |

| Idadi ya blade | 4pcs |

| Nyenzo ya blade | 55 krsi |

| Kipenyo cha roller ya kisu | 650 mm |

| Saizi ya bidhaa iliyokamilishwa | 50 * 50 mm |

| Nguvu ya injini kuu | 55kw |

| Nguvu ya Kulisha motor | 4kw*2 |

| Nguvu ya injini ya pampu ya mafuta | 1.1kw |

| Uzito | 4300kg |

Mashine ya kutengeneza vumbi

WOOD SAWDUST MACHINE: menghancurkan serpihan kayu menjadi serpihan kayu halus

Malighafi ya mwisho kwa ajili ya utengenezaji wa pallets za mbao ni chipsi za mbao, ambazo zinahitaji kusagwa kuwa vipande vya mbao kwa kutumia mashine za kutengeneza chip za mbao.

| Mfano | SL-500 |

| Uwezo | 500kg kwa saa |

| Ukubwa wa pembejeo | 230*500mm |

| Nambari ya nyundo | 40pcs |

| Injini kuu | 22kw |

| Kipenyo cha kiondoa vumbi | 800 mm |

| Saizi ya mwisho ya bidhaa | 10 mm |

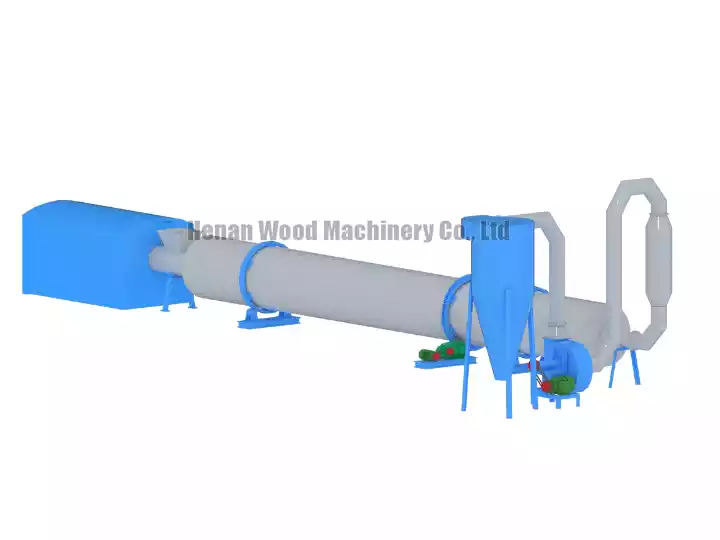

Kikaushia vumbi

MESIN SERBUK KAYU: mengurangi kadar air serpihan kayu

Unyevu wa vipande vya mbao kwa ajili ya uzalishaji wa pallets za mbao unapaswa kuwa chini ya 10%, hivyo dryer inahitajika kwa kukausha.

| Mfano | SL-D800 |

| Nguvu | 3 kw |

| Nguvu ya shabiki | 5.5kw |

| Uwezo | 500-600kg / h |

| Kipenyo | 800mm(D) |

| Unene | 8 mm |

| Uzito | 1800kg |

Gundi na mchanganyiko wa vumbi

| Mfano | SL-900 |

| Nguvu | 7.5kw |

| Dimension | 1.5*1*1.4m |

| Kipenyo | 900 mm |

| Uzito | Takriban 300kg |

| Gundi | Gundi ya resin ya urea-formaldehyde |

PENGADUK LEM: mencampur serpihan kayu dengan lem

Uzalishaji wa pallets za mbao za glued huhitaji kuchanganya chips za kuni na gundi, na mchanganyiko wa gundi unaweza haraka na kikamilifu kuchanganya mbili.

Mashine ya kutengeneza pallet ya mbao

Mashine ya kutengeneza pallet ya mbao:

Mesin pembentuk pallet kayu heat-presses the tray by hot pressing, and the high temperature also has the effect of sterilization.

| Mfano | SL-1000 |

| Nguvu | 15kw |

| Shinikizo | tani 1000 |

| Uwezo | Tengeneza pallet moja hitaji la dakika 4-5 (unaweza kudhibiti mwenyewe) |

| Dimension | 1.9*1.3*4m |

| Uzito | 21000kg |