Машина для изготовления брикетов из опилок перерабатывает древесные материалы, такие как опилки, рисовая шелуха и арахисовая скорлупа, под высоким давлением в полые брикеты. Производительность составляет 250-350 кг/ч. Готовый продукт имеет диаметр 46-50 мм и внутренний диаметр 10-20 мм.

Производимое этим машиной твердое топливо обладает высокой калорийностью и низкими выбросами загрязняющих веществ при сгорании, легко хранится и транспортируется. Поэтому оно очень популярно в топливной промышленности и секторе новой энергии.

Особенности шульи по изготовлению брикетов из опилок

- Прочная конструкция и долгий срок службы

- Корпус и основание имеют интегрированную конструкцию подшипниковой базы, выполненную из цельных стальных пластин для исключительной стабильности.

- Машина для изготовления брикетов из биомассы шульи выполнена из прочных материалов и надежных сварных швов, способных выдерживать длительную высокоинтенсивную работу и обеспечивать долгий срок службы.

- Качественные основные компоненты

- Подшипники прочные (диаметр 100 см), обеспечивают высокую грузоподъемность, плавную работу и снижение износа.

- Шнек изготовлен из стали 45, обладает высокой износостойкостью и твердостью, предотвращает засорение материала и обеспечивает плавное extrusion.

- Форма использует сплав хром-марганец, обеспечивающий высокотемпературную стойкость и сопротивление деформации.

- Мощная и энергоэффективная

- Наша машина для прессования биомассы оснащена мотором с медным сердечником, обеспечивающим мощность, долговечность и стабильную работу.

- Моторы с медным сердечником обеспечивают превосходную проводимость и быстрое рассеивание тепла, что повышает эффективность и увеличивает срок службы по сравнению с алюминиевыми моторами.

- Плавная подача и однородное формование

- Особенность шульи — увеличенный и усиленный бункер для более равномерной подачи и достаточного запаса материала, что повышает эффективность производства и однородность готовой продукции.

Принцип работы машины для опилок

Наша машина для изготовления брикетов из опилок использует присущие древесным материалам свойства. Под высоким температурным и прессовым давлением лигнин в дереве пластифицируется, связывая тонкие волокна в твердые брикеты.

Структура пресса для брикетов из опилок

Эта машина для брикетов состоит в основном из мотора, защитного кожуха, загрузочного отверстия, экструдирующего цилиндра, нагревательного кольца и других компонентов.

Параметры машины для изготовления брикетов из пини кэй

| Модель | SL-50 |

| Емкость | 250-350 кг/ч |

| Власть | 18,5 кВт |

| Температура нагрева | 260-380℃ |

| Размер сырья | Диаметр 3-5 мм |

| Влажность сырья | ≤12% |

| Диаметр готового продукта | 46-50 мм |

| Внутренний диаметр готового продукта | 10-20 мм |

Сырье и готовая продукция

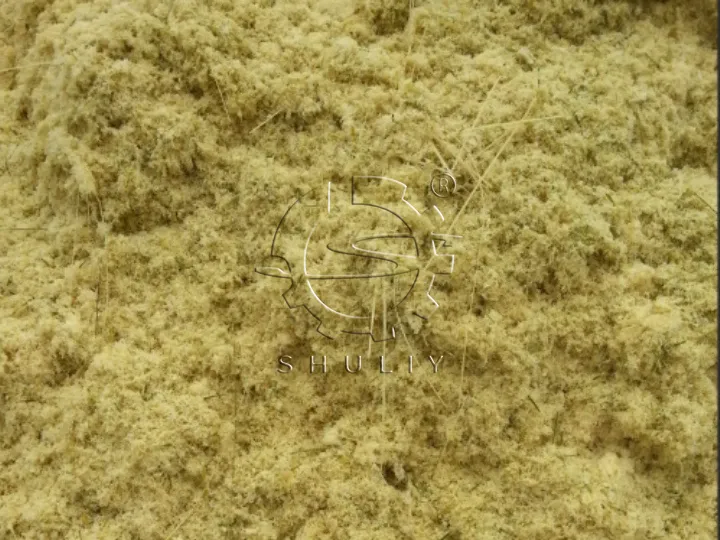

Машина для брикетов из опилок может использоваться с различным сырьем, включая опилки, бамбуковые чипсы, рисовую шелуху, арахисовую скорлупу, древесные стружки, жом и другие древесные материалы (не требуется связующее). Влажность сырья должна быть ≤12%.

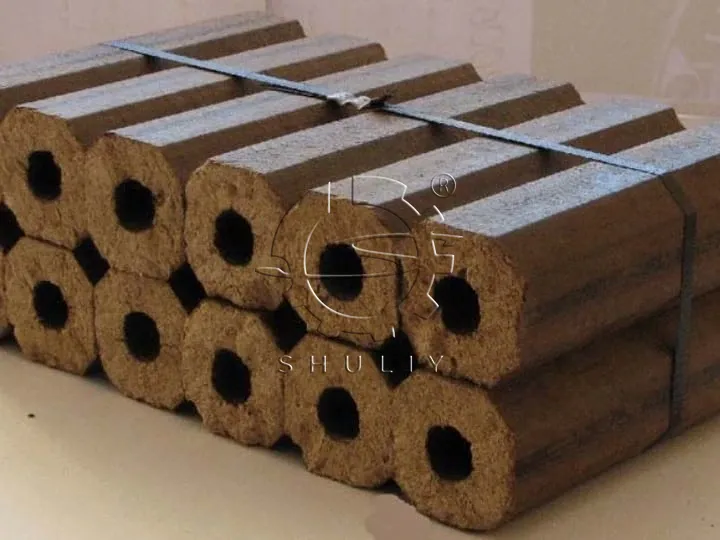

Готовый продукт из машины для брикетов из опилок — полый стержень, длина которого может регулироваться по требованию.

Преимущества брикетов из пини кэй

- Легко загорается: Благодаря своей плотной внутренней структуре и высокому содержанию углерода, брикеты Пини Кэй быстро загораются и горят стабильно.

- Высокая калорийность: Его калорийность превышает таковую обычной древесины более чем на 20%, что обеспечивает высвобождение большего количества энергии и экономию топлива.

- Малое загрязнение: Выбросы загрязняющих веществ, таких как дым и диоксид серы, при сгорании чрезвычайно низки, что делает его экологически чистым биомасляным топливом.

- Высокая плотность: После формовки он обладает высокой плотностью и твердостью, устойчив к разрушению и занимает мало места, что облегчает упаковку, хранение и транспортировку на большие расстояния.

- Эффективное использование ресурсов: Он использует сельскохозяйственные и лесные отходы, такие как бамбуковые щепки, опилки, рисовые шелухи, арахисовые скорлупы и сахарный тростник, как сырье, достигая переработки отходов.

Меры предосторожности при эксплуатации машины для экструдирования древесных брикетов

Чтобы обеспечить нормальную работу и безопасность машины для брикетов из опилок, перед использованием необходимо знать следующие меры предосторожности:

- Во время производства убедитесь, что ток и напряжение мотора в норме, чтобы избежать повреждений.

- Не стойте перед портом выгрузки, когда машина работает.

- Электропроводка должна быть сухой и чистой, при выключении машины отключайте питание.

- Строго предотвращайте попадание камней и железных опилок в бункер. При обнаружении любых неисправностей немедленно останавливайте машину.

- Обеспечьте правильное заземление машины при включении.

Цена машины для прессования биомассы

Цена машины для изготовления брикетов из опилок в основном зависит от различных факторов, включая объем производства, модель, материал, технологический процесс, степень автоматизации и требования к индивидуализации.

Например, чем выше объем производства и чем более современная конфигурация, тем выше цена. Однако при выборе брикетной машины важны не только цена, но и качество. Только машина высокого качества принесет долгосрочную выгоду вашему бизнесу.

Можно ли регулировать длину готового продукта?

Да, положение заслонки можно регулировать, длина заслонки 10-15 см.

Почему сырье не должно быть слишком влажным?

Сырье прилипает к спирали и не может быть выдавлено.

Какие формы доступны для выбора клиентами?

Шестигранные и квадратные отверстия.

Как долго служит машина?

Машина изготовлена из стали и не изнашивается, может использоваться не менее 10 лет.

Нужно ли добавлять клей в сырье?

Не обязательно, но солома и трава требуют древесных чипсов — эти мягкие материалы нуждаются в добавлении твердых веществ.

Успешный кейс шульи по изготовлению брикетов из опилок

Машина для брикетов из опилок шульи экспортируется в различные страны благодаря отличной производительности, включая Пакистан, Болгарию, Конго, США и др. Недавно мы получили хорошие отзывы от наших клиентов в Пакистане.

Этот клиент приобрел нашу машину для брикетов из опилок в основном для прессования бамбуковых чипсов и рисовой шелухи в пини кэй брикеты. Отзыв клиента: “ Эта техника работает стабильно и имеет высокий коэффициент формирования стержней. С момента запуска производство значительно улучшилось. ”

Свяжитесь с нами немедленно!

Шульи — опытный поставщик оборудования для обработки древесины. Мы не только производим эффективные и долговечные машины для брикетов из опилок, но и предоставляем полный комплект оборудования для обработки древесины, такого какмашина для очистки древесины,дробилка для древесины,измельчитель древесных отходови др.

Если вы ищете надежное оборудование для обработки древесины, пожалуйста, свяжитесь с нами. Шульи предоставит профессиональные технические рекомендации и наиболее подходящую конфигурацию оборудования.