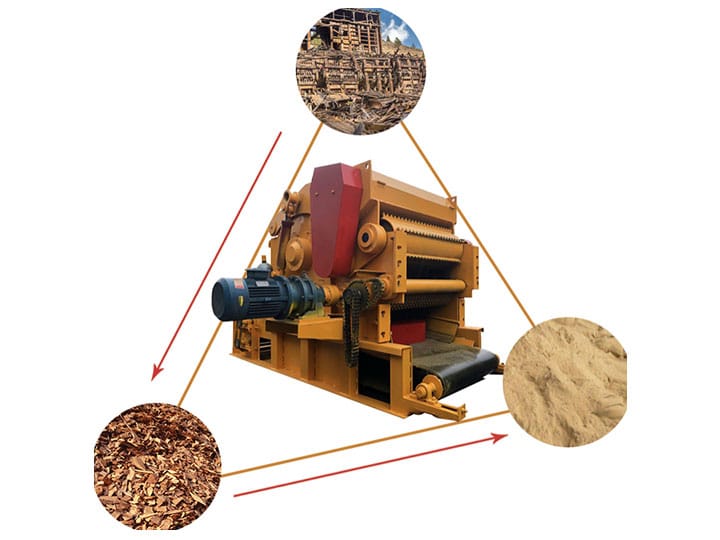

Kapsamlı kırıcı, her türlü büyük malzemeyi (kullanılmış mobilya, çivili kalas, ahşap paletler, büyük çaplı ahşap, kökler, yabani otlar vb.) kırabilen çok fonksiyonlu bir kırma ekipmanıdır. Doğrudan sürüş modu ve güçlü gücüyle her türlü biyokütleyi verimli ve güvenli bir şekilde döküntüye dönüştürebilir. Kompozit kırıcının nihai ürünleri çevre koruma sektörü, mobilya geri dönüşüm sektörü, endüstriyel ürün geri dönüşümü gibi birçok alanda kullanılabilmektedir.

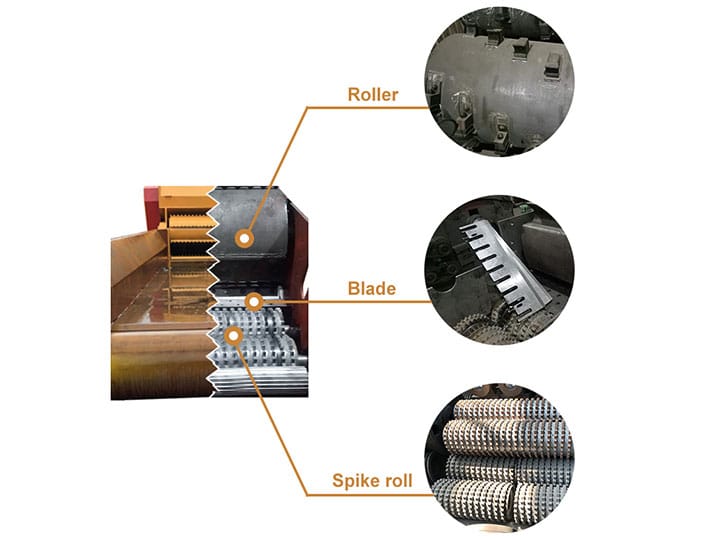

Kompozit kırıcının yapısı

Kompozit kırıcı şu beş bölümden oluşur: iletim, kırma, ayarlama, eleme ve ayırma ve kaba parçacıkların geri dönüşümü ve yeniden kırılması.

- Bulaşma: Kompozit kırıcının ön kısmında malzemenin beslenmesine yardımcı olacak hidrolik sistem bulunmaktadır. Bu kısım motor ve üzerindeki kaplin ve dişliden oluşmaktadır.

- Ezici: Ana şaft üzerinde merkezi bir koni ve dışarıda bir koruma konisinden oluşur. Malzemeler besleme silindirlerinden geçtikten sonra onları bekleyen bir kırma silindiri bulunmaktadır. Seçiminiz koyduğunuz malzemelere bağlı olarak iki çeşit kırma silindirimiz var.

- Ayarlama: Ana mil ayar cihazının altında ve dışında bulunan santrifüj cihazından oluşur.

- Tarama ve sıralama: Bu kısım kaba ve ince eleklerden oluşmaktadır.

- Kaba parçacıkların geri dönüşümü ve yeniden ezilmesi: Kaba eleğin alt tarafında bir kaldırma silindiri ile bağlanan iri taneli bir konveyördür. Kaldırma silindirinde kaldırıcı ve üst kısımda hazneye bağlanan besleyici bulunmaktadır.

Kapsamlı parçalayıcının çalışma prensibi

Çekiç tipi kapsamlı kırıcı çalışırken, motor, rotoru yüksek hızda dönecek şekilde çalıştırır ve ahşap, kapsamlı kırma odasına eşit şekilde girer. Yüksek hızlı dönen çekiç ahşaba çarpar, keser ve yırtar, bu da ahşabın kırılmasına neden olur. Aynı zamanda ahşabın yerçekimi ahşabın kırılmasına neden olur. Yüksek hızda dönen çekiç, çerçevedeki bölmeye ve elek çubuklarına doğru koşuyor. Rotorun alt kısmına bir elek plakası yerleştirilmiştir. Kırılan odunun içindeki elek deliği boyutundan küçük parçacıklar elek plakasından dışarı atılır ve elek deliği boyutundan büyük olan ahşabın direnci elekte kalır. Tahta dövülüp taşlanmaya devam edilir.

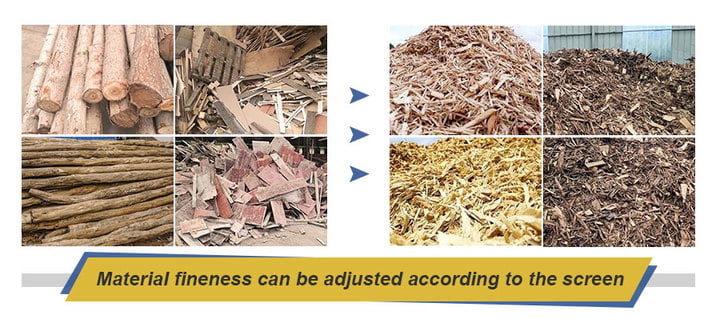

Kapsamlı kırıcı için hammaddeler

Bu tür kapsamlı makine tam işlevli bir kırıcıdır. Buraya istediğiniz her şeyi koyabilirsiniz. Vida ile birlikte mobilya tahtaları gibi büyük malzemeler ve karmaşık ahşap paletler de konulabilir. Aynı ham maddeler arasında atık ambalaj, şablonlar, plakalar, dallar, ahşap kutular, tepsiler, mısır sapları, kütükler ve diğer atık ahşap malzemeler ve silaj kırılmış malzemeler bulunmaktadır.

Kapsamlı kırıcının ana özellikleri

- Mevsimsel iklim ve diğer dış koşullardan etkilenmeden, farklı coğrafi ve topografik koşullar altında ekipmanın kurulumunu ve kullanımını test etmek için kullanılabilecek, temel oluşturmanın neden olduğu kurulum süresinden ve insan gücünden, malzeme kaynaklarından ve finansal tüketimden tasarruf sağlayan, alt zemin içermeyen tasarımı benimseyin.

- Tam otomatik kontrolü, otomatik besleme ve boşaltmayı benimseyin, üretim kapasitesini artırın ve insan-makine ayrımını yapın, makinenin çalışmasının güvenlik faktörünü artırın.

- Geleneksel bant beslemeyle karşılaştırıldığında besleme daha düzgündür ve üretim kapasitesi büyük ölçüde artar.

- Fabrikamız tarafından bağımsız olarak geliştirilen, uzun servis ömrü ve düşük bakım maliyeti ile özel küçük kesici takımları benimseyin.

- İkincil bir boşaltma sistemiyle donatılan kullanıcılar, boşaltma yönünü gereksinimlere göre değiştirebilir ve kullanımı esnek bir şekilde yönetebilir.

- Kapsamlı ahşap kırıcı, bambu kauçuk levhadan veya mal palet çivilerinden korkmayan ahşap kırma makine ekipmanıdır.

- Kabuk açma ve kapama için hidrolik açma cihazı olan hidrolik sistemin kullanılması, bakım emek yoğunluğunu etkili bir şekilde azaltabilir, bakım işi verimliliğini artırabilir, bakım çalışma süresini kısaltabilir.

- Kutu kırıcının izleme sistemi, kırıcının çalışma durumunu herhangi bir zamanda izleyebilir. Makinenin emniyetli ve güvenilir şekilde çalışmasını sağlamak için izleme sinyali ana kontrol sistemi ile kilitlenebilir.

Müşteri vakaları kapsamlı kırıcının

Geçtiğimiz günlerde Tayland'dan bir sipariş aldık. Başlangıçta müşterimiz, 5 yıl önce firmamızdan geleneksel bir makine satın alan yerel bir arkadaşını ziyaret ediyordu. Bu yüksek kapasiteli bileşik kırıcıya aşık oldu ve arkadaşından onu nereden satın alabileceğini söylemesini istedi. Eski müşterimiz olan arkadaşı, daha iyi performansa sahip yeni makinemizi almasını önerdi.

Yeni müşteri, bölgede bir fabrika şubesi olup olmadığını sormak için bizimle iletişime geçti. Üzgünüz ve kendisine yerel bir şubemizin olmadığını ancak internet üzerinden canlı yayın yapacağımızı söyledik. Daha sonra canlı yayını izledi ve burada tüm ürün grubunu gösterdiğimizi gördü. Çok mutluydu ve kısa sürede kapsamlı bir makine satın aldı.

Son olarak yeni taç salgını bittiğinde derhal Çin'deki fabrikaları ziyaret edip daha fazla makine satın alacağını söyledi.