Bir ağaç büyüdüğünde kabuğu esas olarak besin maddelerini taşımak için kullanılır ve aynı zamanda ağacın soğuğu ve sıcağı önlemesinde de önemli bir rol oynar. Logaritmik ahşap işlemede ikisi genellikle ayrı ayrı kullanılır ve farklı işlevlere sahiptir. Ahşap kabuk soyma makinesi, ticari ahşap işlemede önemli bir araçtır.

Neden ahşap kabuk soyma makinesini kullanmalısınız?

Geçmişte ahşap ekipmanları işlerken soyma işlemine hiç gerek duyulmuyordu. Ahşabın çok geniş bir fonksiyon yelpazesine sahip olduğunu herkes bilir. İnsanların yaşaması için evler inşa etmek için kullanılabilir ve aynı zamanda üst düzey mobilyalar yapmak için de kullanılabilir. Ayrıca bazı el sanatlarının yapımında da kullanılabilir. kağıt yapımı için malzeme. Peki kabuğu ne için kullanılabilir? Sadece çöpe atmak için mi kullanılabilir? Aslında kabuğu da çok faydalı bir şeydir. Artık ağaç kabuğundan yapılmış ağaç kabuğu resimleri var. Kabuğun ezilmesinden sonra kağıt yapımında malzeme olarak da kullanılabilir. Peki ağaç kabuğu ağaçla nasıl birleşerek onları ayırabilir?

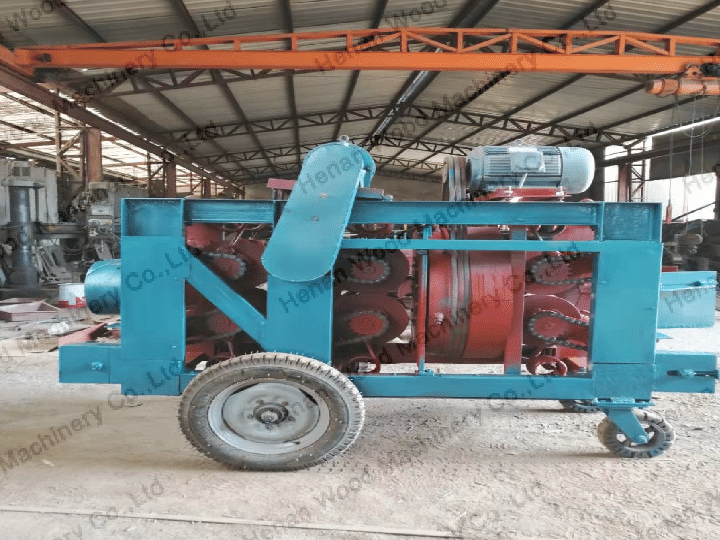

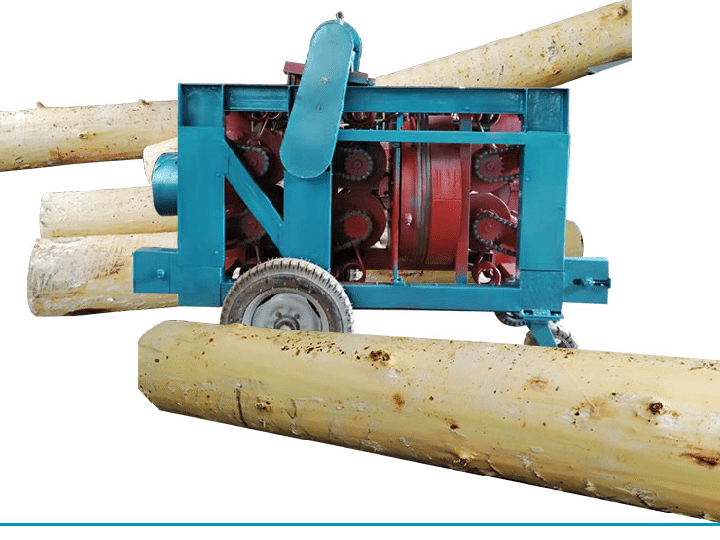

Ahşap kabuk soyma makinesinin tanıtımı

Bu aşamada, ahşap kütük soyar makinesi ekipmanını kullanmanız gerekiyor. Bu ayrıca ahşap soyar makinesi veya kaplama soyar makinesi olarak da adlandırılır. Ahşap soyar makinesinin çalışma prensibi: kütükleri, dalları ve diğer ahşapları tambura koyun, besleme panjurlarını kapatın, makineyi çalıştırın, saat yönünde çalıştırın ve ahşap tamburda. Makinenin çalışmasıyla birlikte, soyma bıçağı ahşabın kabuğunu soyabilir. 15 dakika sonra, makineyi kapatın, boşaltma panjurlarını açın, ardından makineyi başlatın ve iki dakika boyunca saat yönünün tersine çalıştırın, soyulan ahşap tamburdan otomatik olarak dışarı çıkabilir ve soyma oranı 'e ulaşabilir. Birçok sektör, ahşap unu için daha yüksek gereksinimlere sahiptir. Kabuğun çıkarılmaması durumunda, safsızlıklar daha büyük olacaktır, bu nedenle ahşap soyar makinesi ekipmanı da kullanılacaktır.

Ahşap soyma makinesinin özellikleri:

1. Dört taraflı kesme aletlerinin kullanılması, kullanımı kolay ve düşük maliyetli.

2. Kesici kafanın basınç regülasyonu, gelişmiş yapı ve güvenilir performans ile hidrolik basınçla kontrol edilir.

3. Besleme mekanizması, dondurulmuş ahşap, oymalı ahşap, okaliptüs, meşe, karaağaç vb. gibi soyulması zor ağaç türleri üzerinde iyi bir soyma etkisine sahip olan kademesiz hız değişimini benimser.

4. Yüksek soyulma berraklığı, yüksek verimlilik ve çok az ahşap hasarı.

Ağaç kabuğu soyma makinesinin kabuk soyma verimliliğini etkileyen üç faktör

1. Soyma makinesinin gücü, büyük ağaç kabuğu soyma makinesi elbette daha verimlidir ve küçük makine daha az verimlidir.

2. Ahşabın nemi: Normal şartlarda, en iyi etkiyi elde etmek için ahşabın birkaç gün kurutulması ve ardından soyulması önerilir. Ayrıca mevsim ahşabın soyulma oranını da etkiler. Genel olarak yazın soyulma oranı 95%’dir. Ve kışın 80%'de.

3. Ahşabın eğriliği: Ahşap soyma makinesi, ahşap parçanın malzemenin iç yüzeyinde tekrar tekrar hareket etmesini sağlamak için rotorun soyma dişleriyle ürettiği benzersiz kuvveti kullandığından, ahşap parça ve dişler, ahşap Segment ve ahşap segment, Ahşap segment ile silo arasındaki sürekli sürtünme, darbe ve ekstrüzyon, verimli soyma etkisini elde etmek için ağaç kabuğu hızla ayrılır, bu nedenle ahşabın bükülmesi ahşabın kırılmasını önlemek için çok büyük olmamalıdır. temas edemediği için ayrılıyor dişler. izin verilen maksimum bükülme derecesi genellikle 8%'dir.