목재 팔레트는 저렴한 가격과 견고한 구조로 인해 산업 생산에서 취급 및 운송에 널리 사용되는 재료가 되었습니다. 이러한 목재 팔레트는 폐기된 후 분쇄 및 압축을 위해 재활용되거나 연료로 만들어져 자원 재활용을 실현할 수 있습니다. 이 과정에서 목재 팔레트 분쇄기는 분리할 수 없습니다. 목재 팔레트 분쇄기는 어떻게 작동합니까?

목재 팔레트 분쇄기 소개

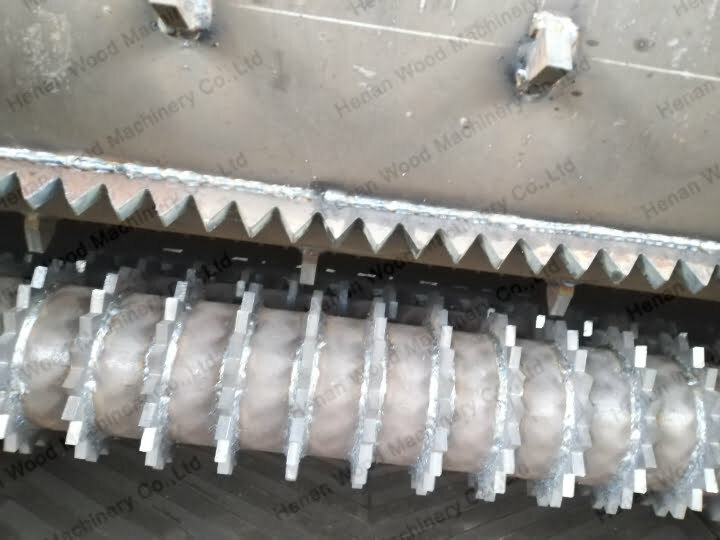

폐목재 파렛트를 재활용한 후 일반적으로 분쇄하여 판재 압착, 바이오매스 펠릿 제조, 발전용 연료봉 제조 등의 용도로 사용합니다. 목재 팔레트의 분쇄는 일반적으로 모터에 의해 구동되어 감속기가 작동하는 이중 샤프트 분쇄기를 사용하며 두 샤프트의 롤링은 블레이드를 롤러로 구동하여 목재를 작은 크기로 자르고 부수는 것입니다. 장비는 작동이 간단하고 수동 공급만 필요하며 자동화 수준이 높습니다. 고품질 고합금 블레이드를 사용하면 부서진 목재 팔레트의 요구 사항을 충족할 수 있으며 경도가 높고 착용하기 쉽지 않으며 수명이 길다.

목재 팔레트 분쇄기 매개변수

| 모델 | 힘 | 생산하다 | 무게 | 컨베이어 벨트 길이 |

| 1000 | 110kw | 8톤 | 6.5톤 | 4미터 피드, 10미터 출력 |

| 1300 | 132kw | 10톤 | 8.5톤 | 4미터 피드, 10미터 출력 |

| 1400 | 160kw | 15톤 | 10.5톤 | 4미터 피드, 10미터 출력 |

| 1600 | 220kw | 20톤 | 13.5톤 | 4미터 피드, 10미터 출력 |

목재 팔레트 분쇄 산업의 전망

목재 팔레트의 재활용 가격은 저렴하며, 처리 후 만들어진 완제품은 널리 사용 및 판매됩니다. 엄청난 이익 전망을 가진 좋은 프로젝트입니다. 프로젝트의 전처리 과정에서 목재 팔레트 분쇄기가 중요한 역할을 하기 때문에 목재 가공 산업에서는 고효율 목재 팔레트 분쇄기가 매우 중요합니다.